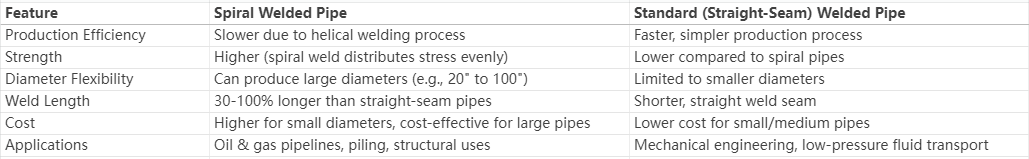

Steel pipes are essential in industries like oil & gas, construction, and infrastructure. They come in various types, primarily categorized by manufacturing methods—seamless and welded. Among welded pipes, spiral welded pipes and straight-seam (longitudinal) welded pipes are the most common.

This article explores the differences between standard steel pipes and spiral welded pipes, focusing on production methods, applications, and advantages.

· Produced using methods like Electric Resistance Welding (ERW), Submerged Arc Welding (SAW), or Gas Welding

· Can be straight-seam (longitudinal) welded

· Common in small to medium diameters (e.g., Φ219-Φ2032, wall thickness 5-18mm)

· Materials: Q235, Q345, X42-X70 grades

· Made by helically bending steel strips or plates and welding the seams

· Uses Submerged Arc Welding (SAW) for high-strength joints

· Ideal for large-diameter pipes (used in oil & gas transmission, piling, and bridges)

· Key advantage: Can produce different diameters using the same strip width

1. Uniform Strength Distribution – The spiral weld spreads stress evenly, enhancing durability.

2. Flexible Production – A single strip width can produce multiple pipe diameters.

3. No Length Restrictions – Continuous bending allows for custom pipe lengths.

4. High Dimensional Accuracy – Spiral welding ensures better roundness and precision.

5. Ideal for Large-Diameter Pipes – More cost-effective than straight-seam alternatives for big projects.

o Low-pressure fluid transport

While standard welded pipes are cost-effective for small to medium applications, spiral welded pipes excel in large-diameter, high-strength uses like oil & gas pipelines. The choice depends on project requirements, budget, and structural demands.

For industries needing high-strength, large-diameter piping, the spiral welded pipe remains the superior choice due to its durability and manufacturing flexibility.