In the field of industrial piping systems, EFW steel pipe (Electric Fusion Welded steel pipe) plays a vital role in applications that demand high corrosion resistance, precise dimensional control, and reliable weld integrity. To ensure product quality and consistency, manufacturers and engineers rely on internationally recognized standards — primarily ASTM and ASME — which define the technical requirements for these welded pipes.

This article provides a detailed overview of the ASTM and ASME standards governing EFW steel pipe, explaining their scope, material grades, testing methods, and compliance guidelines.

An EFW steel pipe is produced by the process of electric fusion welding, where an electric arc is used to fuse the edges of a rolled plate or coil to form a longitudinally welded pipe. Unlike ERW (Electric Resistance Welded) pipes, EFW pipes are generally manufactured for high-pressure and high-temperature applications, such as in the chemical, power generation, and oil & gas industries.

EFW pipes are typically used in stainless steel and alloy steel grades, ensuring superior resistance to corrosion, oxidation, and creep.

Both ASTM (American Society for Testing and Materials) and ASME (American Society of Mechanical Engineers) establish comprehensive specifications for steel pipes used in industrial systems.

While ASTM standards define chemical composition, mechanical properties, and testing requirements, ASME incorporates these materials into design codes such as ASME B31.1 (Power Piping) and ASME B31.3 (Process Piping) for safe engineering applications.

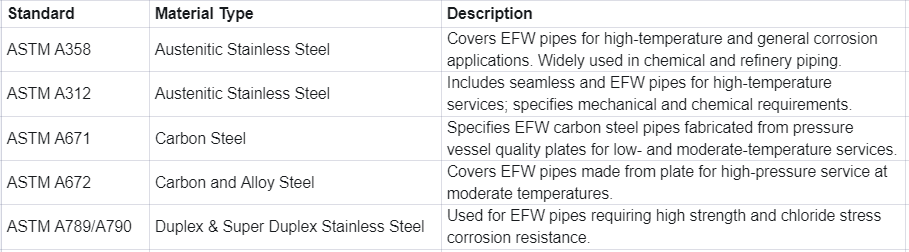

Below are the most common ASTM standards related to EFW steel pipe production:

While ASTM standards define how the pipe is made, ASME standards define how the pipe is used in engineered systems.

EFW steel pipes meeting ASTM specifications are often certified under ASME Section II (Materials), which ensures compatibility with pressure vessel and piping design codes.

For example:

· ASME B31.3 references ASTM A312 and A358 pipes for process piping systems.

· ASME Section VIII allows ASTM A671 and A672 materials for pressure vessel fabrication.

Compliance with both ASTM and ASME ensures that an EFW steel pipe meets stringent performance, safety, and reliability criteria.

To comply with ASTM/ASME standards, several non-destructive and mechanical tests must be performed during and after manufacturing:

· Hydrostatic Testing: Verifies pressure containment.

· Ultrasonic or Radiographic Testing (UT/RT): Detects internal weld defects.

· Tensile and Impact Testing: Confirms mechanical properties such as yield and ultimate tensile strength.

· Visual and Dimensional Inspection: Ensures alignment, weld reinforcement, and wall thickness uniformity.

Manufacturers must maintain full traceability of materials, heat numbers, and inspection reports to demonstrate conformance.

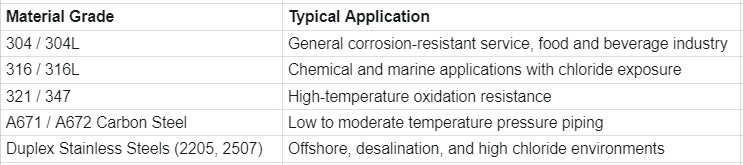

When choosing an EFW steel pipe, engineers should consider the following factors:

1. Operating Temperature and Pressure – Match the material grade to service conditions.

2. Corrosion Resistance – Select stainless or duplex alloys for aggressive environments.

3. Weld Integrity – Ensure compliance with ASTM testing standards.

4. Code Compliance – Verify compatibility with ASME B31.1 or B31.3 systems.

Proper material selection and adherence to recognized standards ensure long service life and safe operation.

Understanding ASTM and ASME standards is essential for ensuring that an EFW steel pipe meets the required quality, safety, and performance expectations in demanding industrial environments. By following these international specifications, manufacturers and end users can achieve full traceability, enhanced reliability, and compliance with global engineering codes.

Whether used in refinery systems, power plants, or offshore platforms, EFW pipes built to ASTM and ASME standards continue to be the backbone of high-integrity piping solutions worldwide.