Do you feel confused by the many types of industrial pipes available for your project? You might worry about choosing the wrong pipe for high-pressure jobs. A SAWL steel pipe is a Longitudinally Submerged Arc Welded pipe. It is made by bending steel plates and welding the seam. This pipe is famous for high strength and reliability. It is the same as LSAW pipe. It is the top choice for oil and gas transport.

I know that finding the right piping solution is hard. There are too many acronyms and standards. I have seen many project managers struggle with this. I want to help you understand this product fully. I will explain the definition, the process, and the uses. This guide will save you time. You will not need to look elsewhere.

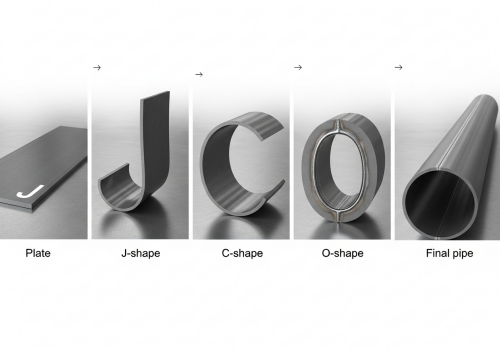

You might think that making large steel pipes is a simple rolling process. But the reality is a complex series of steps that ensures safety. The manufacturing method often uses the JCOE process. We take a flat steel plate and bend it into a "J" shape, then a "C" shape, and finally an "O" shape. Then, we use submerged arc welding to seal the seam from both inside and outside.

Let me take you deeper into the factory floor. The production of a sawl steel pipe is fascinating. It starts with raw material selection. We use high-quality steel plates. This is different from other pipes that use steel coils. We inspect the plate surface first. We remove rust and oil. Then, we cut the plate to the exact width needed for the pipe diameter. We also mill the edges. This prepares the metal for a strong weld later. The forming stage is critical. We usually use the JCOE method. A huge machine presses the plate. It bends one side to look like a J. Then it bends the other side to look like a C. Finally, it presses the middle to make an O shape. Now it looks like a pipe, but it has an open seam. We join this seam with pre-welding. This holds the shape. The most important part is the Submerged Arc Welding (SAW). We weld the inside first, then the outside. We use a special flux to cover the weld area. This protects the hot metal from the air. It prevents defects. After welding, we do something called "Mechanical Expansion." We expand the pipe slightly from the inside. This makes the pipe perfectly round. It also relieves stress in the metal. This ensures the pipe fits perfectly in your pipeline. We finish with testing, like X-rays and ultrasonic scans. We never skip these checks at Centerway Steel.

Are you worried that the pipe you buy will not meet the engineering requirements of your country? This is a common fear in global projects. SAWL pipes follow strict international standards like API 5L and ASTM A252. They cover a wide range of sizes. Diameters usually run from 350mm to 1500mm. Wall thickness can go up to 80mm. These specs ensure the pipe handles heavy loads.

You need to know the numbers to make a good decision. In my 18 years in the industry, I have seen that mismatched specs cause big delays. The sawl steel pipe is very flexible in size. The diameter is usually large. We can make them from 16 inches up to 60 inches or more. The length is also customizable. We usually ship them in 6 to 12-meter lengths. But we can adjust this for your shipping container. The standards define the quality. The most common one is API 5L. This is for the oil and gas industry. It has two levels: PSL1 and PSL2. PSL2 is stricter on chemicals and strength. If you are building a structure, you might use ASTM A252. For European projects, we often see EN10210 or EN10219. Here is a simple table to help you match standards with applications:

| Standard | Common Grades | Typical Application |

|---|---|---|

| API 5L | Gr.B, X42, X52, X60, X70 | Oil & Gas Pipelines, Petroleum Transport |

| ASTM A252 | Grade 1, 2, 3 | Piling, Construction, Foundation Support |

| ASTM A671/A672 | CC60, CC65, CC70 | Atmospheric and Lower Temperatures |

| EN 10210 / 10219 | S275, S355 | Structural hollow sections, Offshore platforms |

Do you wonder if you could save money by buying a different, cheaper type of welded pipe? You need to balance the budget with safety risks. You should choose SAWL pipe for high-pressure and critical applications. It offers better dimensional accuracy than spiral welded pipes. The longitudinal weld is shorter and has less stress. This makes it safer for long-distance energy transport.

Let me explain the value here. There are other pipes, like spiral welded pipes (SSAW). They are often cheaper. But a sawl steel pipe has distinct advantages. The main one is the weld length. The weld on a SAWL pipe is a straight line. It is the shortest path between two points. A spiral pipe has a much longer weld. A longer weld means a higher chance of defects. Also, the SAWL process includes that "cold expansion" step I mentioned earlier. This makes the pipe very true to size. When you connect two pipes in the field, they fit together easily. This speeds up your construction time. Time is money in our business. The strength is also superior. These pipes can handle huge pressure. That is why oil giants like Shell and ExxonMobil use them for main lines. They also resist corrosion well when coated. We can apply 3PE, FBE, or other coatings. This is vital for subsea lines. Consider the application scope:

1. Energy: Oil, gas, and natural gas transmission.

2. Water: Heavy-duty water treatment and sewage systems.

3. Structures: The pipe is so strong it is used for columns in skyscrapers. It is used for piling in bridges. It is used for legs on offshore drilling rigs. When safety and longevity are the main goals, this pipe is the best answer. It handles stress better than any other welded pipe option.

SAWL steel pipe is the top choice for high-pressure pipelines and heavy structures due to its strength and precise JCOE manufacturing. At Centerway Steel, we provide these pipes globally with full quality certification.