Are you confused by the technical acronyms on your pipe requisition list? Many purchasing managers struggle to distinguish between welding methods, and this confusion often leads to costly ordering mistakes. I will explain the specific differences so you can buy the right steel pipe with confidence. The main difference between ERW and EFW pipe lies in the welding method. ERW (Electric Resistance Welding) uses pressure and electrical resistance to join metal without filler. EFW (Electric Fusion Welding) melts the metal, often using an electron beam or laser, to fuse the seam. EFW is generally stronger and more expensive.

We need to understand these details. A wrong choice affects your project budget. A wrong choice affects safety. I see this happen often. Let's look closely at the details.

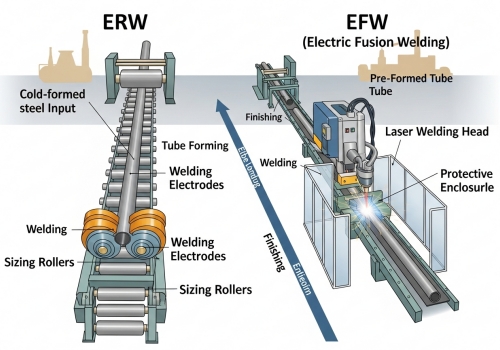

Does the way a machine forms the pipe really change the final quality? Yes, the manufacturing process dictates the strength, and ignoring this step can cause pipeline failures later. I want to show you exactly how the factory floor operates for each type. The ERW process uses a high-frequency current to heat the steel edges before pressing them together, while the EFW process melts the metal completely to fuse the joint. This distinction creates the fundamental difference between erw and efw pipe regarding structural integrity.

I have visited many factories since Centerway Steel started in 1996. I watch the machines work. It is fascinating. For ERW pipes, the process starts with a flat strip of steel. We call this a coil. The machine unrolls the coil. Rollers shape it into a cylinder. Then, a high-frequency electrical current passes through the edges. This current creates heat. The heat comes from the resistance of the steel. The edges get hot and red. Then, rollers press the edges together. This makes a bond. We do not use extra filler metal here. The machine trims the flash, or the extra metal, from the seam. This leaves a smooth surface. This mechanical bonding is fast and efficient. For EFW pipes, the process is different. We also form the steel into a cylinder. However, we use high-energy beams. This is often an electron beam or a laser. This beam hits the joint. It generates very high heat. This heat melts the steel edges. The metal turns to liquid for a moment. Then it fuses together. This is a true fusion process. The material becomes one solid piece. The heat moves fast. This means the heat does not spread far. The "Heat Affected Zone" is small. This makes the pipe uniform. The structure of the weld looks very much like the rest of the pipe. Because the metal actually melts and mixes, the bond is molecularly consistent.

| Feature | ERW (Electric Resistance Welding) | EFW (Electric Fusion Welding) |

|---|---|---|

| Heat Source | Electrical Resistance | High-energy Beam (Electron/Laser) |

| State of Metal | Heated, Plastic State | Melted, Liquid State |

| Filler Metal | No | No (Autogenous) |

| Weld Appearance | Visible seam (unless trimmed) | Very smooth, hard to see |

| Speed | Faster Production | Slower Production |

Are you worried about pipes bursting under extreme pressure or harsh chemicals? Choosing the weaker option for a critical line is a nightmare for any engineer or purchasing manager. You need to know which pipe stands up to the toughest tests. EFW pipe offers superior performance in high-pressure and corrosive environments because the fusion process creates a uniform, dense weld that mimics a seamless structure. ERW pipe is excellent for standard pressure applications but has limitations in extreme conditions.

I remember a project in the Middle East. A client wanted to save money. They looked at the difference between erw and efw pipe prices. They chose the cheaper option for a high-pressure line. It was a mistake. We helped them fix it later with the right products. It is vital to match the pipe to the stress level. EFW pipes are very strong. The fusion makes the weld area just as strong as the rest of the pipe. The metal grain structure is uniform. This is important for high pressure. It is also important for corrosion. Corrosive fluids attack weak points. A bad weld is a weak point. EFW does not have this weak point. It acts almost like a seamless pipe. We often suggest EFW for the petrochemical industry. It is good for oil refineries. It is good for chemical plants. It handles heat well. The uniformity prevents the "grooving corrosion" that sometimes attacks the seam of lesser pipes. ERW pipes are also good. They are strong enough for many jobs. We use them for water transport. We use them for oil and gas transmission over long distances. They are great for construction piling. They work well for fencing and scaffolding. However, the weld seam is a distinct area. In the past, this seam had problems. Modern technology is better. High-frequency welding fixes many old issues. But for very critical, high-stress jobs, engineers prefer the uniformity of EFW. If the pressure fluctuates rapidly, EFW is the safer bet due to better fatigue resistance.

· ERW Durability: Good for standard utility life cycles.

· EFW Durability: Excellent for harsh, aggressive environments.

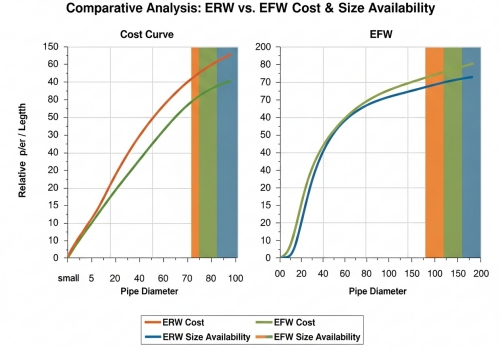

Do you know which ASTM standards match your project requirements and your budget constraints? Buying the wrong specification results in rejected materials and project delays. I will break down the sizes and standards to help you source the correct item. ERW pipe is the most cost-effective choice for sizes up to 24 inches, while EFW allows for larger diameters and thicker walls suitable for specialized projects. Understanding the standards like ASTM A53 versus ASTM A672 is vital for your procurement strategy.

Price is always a big factor. My German clients always ask about value. They want quality, but they do not want to waste money. Finding the balance requires knowing the market capabilities. ERW manufacturing is efficient. The machines run fast. This makes the production cost low. If you need standard sizes, ERW is the best price. The sizes usually range from 1/2 inch to 24 inches. Some factories can go up to 48 inches. But the tooling cost is high for big sizes. If you need a lot of standard pipe, buy ERW. It is readily available. We keep a lot of this in stock at Centerway Steel. It is perfect for large volume orders where the pipe serves a utility function rather than a high-criticality function. EFW manufacturing is slower. The equipment is expensive. This makes the pipe cost more. However, EFW is flexible. We can make very large pipes. We can go up to 100 inches in diameter. We can make pipes with very thick walls. This is hard for ERW machines. If you need a custom size for a pressure vessel, EFW is the answer. It is a good alternative to seamless pipe. Seamless pipe is very expensive in large sizes. EFW gives similar performance for a better price than seamless. It bridges the gap between the cost of welded pipe and the performance of seamless pipe. Here are the common standards we see in purchase orders:

· ASTM A53: Standard for mechanical and pressure applications.

· ASTM A252: Standard for piling pipes.

· API 5L: Standard for line pipe (Oil and Gas).

· ASTM A672: EFW steel pipe for high-pressure service at moderate temperatures.

· ASTM A691: EFW carbon and alloy steel pipe for high-pressure service at high temperatures.

· ASTM A358: EFW austenitic chromium-nickel stainless steel pipe for high-temperature service. The difference between erw and efw pipe is clear in the standards. An A53 pipe is usually ERW. An A672 pipe is always EFW. You must check your data sheet. Do not swap them without asking the engineer.

ERW is cost-effective for standard needs, while EFW offers superior strength for high-pressure, critical applications. Choose wisely based on your project's specific stress and budget requirements.