You face constant pressure to lower project costs without risking structural integrity or safety. Finding a pipe solution that balances price with high performance is stressful. This type of pipe offers the perfect solution for your budget and engineering needs. High frequency welded pipe (HFW) is a superior type of ERW steel pipe produced using high-frequency current to heat steel edges. This process creates a bond without filler material, offering high weld strength, tight dimensional accuracy, and significant cost savings compared to seamless pipes.

I know that technical specifications can feel overwhelming when you just want a reliable product. But understanding this specific welding method helps you buy better materials. It ensures you don't overpay for seamless pipes when you don't need to. Let's look at exactly how we make these pipes and why they work.

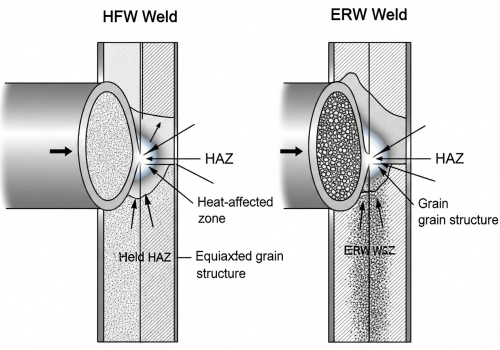

You worry about weld defects causing leaks or structural failures in your construction projects. These failures happen when manufacturers use outdated or imprecise welding methods. The HFW process uses the "skin effect" and "proximity effect" of high-frequency current. This concentrates heat precisely at the edges of the steel strip. It results in a narrow Heat Affected Zone (HAZ) and a much stronger weld than standard low-frequency methods.

I want to explain this process simply so you can see why it matters for your procurement. We start with a flat steel coil. We unroll it and form it into a round shape. The magic happens at the welding stage. We use a high-frequency current, usually between 100 kHz and 500 kHz. This current does not travel through the whole pipe. It stays on the very surface of the steel edges. This is what we call the "skin effect." The heat is intense and very focused. We then press the edges together. We do not use any extra filler metal. The steel fuses with itself. This makes the chemical composition of the weld almost the same as the base metal. After welding, the pipe goes through heat treatment. This is a vital step. The rapid heating and cooling can leave stress in the metal. We use annealing to treat the weld seam. This removes the stress and makes the pipe tough. If a supplier skips this, the pipe might crack. We at Centerway Steel never skip this step. Here is how HFW compares to other common pipe types you might buy:

| Feature | HFW Pipe | Seamless Pipe | LSAW Pipe |

|---|---|---|---|

| Manufacturing Method | High-Frequency Induction | Extrusion/Rotary Piercing | Submerged Arc Welding |

| Production Efficiency | Very High | Low | Medium |

| Dimensional Accuracy | High (Uniform Thickness) | Medium | High |

| Cost | Low/Medium | High | High |

| Weld Seam | Yes (Invisible/Flush) | No | Yes (Visible) |

| Main Application | Oil, Gas, Construction | High Pressure, Critical | Large Diameter Oil/Gas |

Projects get delayed when materials arrive with defects or fail to meet site requirements. You cannot afford downtime or replacement costs in the middle of a job. High frequency welded pipe provides excellent concentricity and wall thickness uniformity. They are much cheaper than seamless pipes but strong enough for oil, gas, and piling lines.

I have worked with many purchasing managers who used to buy only seamless pipes. They thought seamless was the only safe option. But technology has changed. HFW is now a robust alternative.

1. Cost Efficiency This is the biggest benefit for you. The production speed of HFW is fast. We can produce thousands of meters a day. This efficiency lowers the unit cost. For a large pipeline or a big construction structure, the savings are huge. You can use that budget for other parts of your project.

2. Tight Tolerances Because we make HFW from rolled steel coils, the thickness is very even. Seamless pipes are made by poking a hole through a hot billet. This can cause the wall to be thick on one side and thin on the other. HFW does not have this problem. When your engineers connect pipes, they fit perfectly. This speeds up installation.

3. Versatility in Application You can use these pipes for almost anything. They are great for transporting oil and natural gas. They are tough enough for high pressure. In your construction industry, they are perfect for piling and structural supports.

4. Surface Quality The surface of these pipes is smooth. This makes it easy to apply coatings. If you need anti-corrosion coating (like 3LPE or FBE), HFW is the best base. The coating sticks better and lasts longer. Here are the standard specifications we often supply at Centerway Steel:

| Property | Description |

|---|---|

| Standard Grades | API 5L (B to X80), ASTM A53, EN10219 |

| Outer Diameter | 21.3 mm to 610 mm (approx) |

| Wall Thickness | 1.8 mm to 22 mm |

| Length | 5.8m, 6m, 11.8m, 12m (Customizable) |

| Ends | Plain, Beveled, Threaded |

Many suppliers promise quality but deliver scrap that fails under pressure. It ruins your reputation and puts your project at risk. You must demand specific tests like ultrasonic inspection and hydrostatic testing. Always check for certifications like ISO 9001 and API 5L from your manufacturer.

As a purchasing manager, you need to know what to ask for. Do not just look at the price tag. A cheap pipe with a bad weld is the most expensive pipe you will ever buy. It will fail. At Centerway Steel, we follow a strict Quality Control (QC) plan. When you look for a supplier, ask them if they do these tests:

1. Ultrasonic Testing (UT): We use sound waves to check the weld seam. This finds hidden cracks inside the metal that you cannot see with your eyes. We check 100% of the weld seam.

2. Hydrostatic Testing: We fill every pipe with water and pressurize it. We hold the pressure for a set time. This proves the pipe will not leak on your site.

3. Flattening Test: We take a sample ring of the pipe and crush it. The weld must not crack. This tests the ductility of the weld.

4. Visual and Dimensional Check: We measure the diameter, thickness, and length. We check the straightness. Raw Material Matters The quality of high frequency welded pipe depends on the steel coil. We only source coils from top steel mills in China. If the coil has bad chemistry, the pipe will be bad. We check the Mill Test Certificate (MTC) for every coil. Third-Party Inspection I know you might be in Germany or elsewhere. You cannot always visit the factory. We welcome third-party inspectors. Companies like SGS, BV, or TUV come to our factory often. They inspect the goods for our clients. This gives you peace of mind. Here is a simple checklist for your next order:

| QC Step | Purpose | Required? |

|---|---|---|

| Material Certificate | Verify steel grade and chemistry | YES |

| Hydrotest Report | Prove pressure capability | YES |

| UT Report | Detect internal weld flaws | YES |

| Surface Check | Ensure no rust or dents | YES |

We provide all these documents. We want to be your one-stop partner. We handle the production, the testing, and the shipping. You just place the order and wait for the goods.

High frequency welded pipe offers the best balance of strength, precision, and cost for your construction and energy projects. By choosing a reputable supplier like Centerway Steel, you ensure quality and safety.