You need to source welded pipes for your project, but the technical terms are confusing. You see ERW and HFW on different data sheets, and you worry about buying the wrong specification for your client. The main difference in hfw vs erw pipe lies in the welding frequency. ERW (Electric Resistance Welded) is the broad category of resistance welding. HFW (High-Frequency Welded) is a superior type of ERW that uses high-frequency current to create stronger, more reliable welds, specifically required for critical oil and gas pipelines.

I have worked at Centerway Steel since 1996. Over these decades, I have seen many purchasing managers struggle with these two acronyms. It is common to see "ERW" on an older specification sheet when the engineer actually needs modern high-frequency performance. If you do not understand the distinction, you might overpay for a feature you do not need, or worse, buy a pipe that fails under pressure. I want to explain this simply so you can make the right choice for your company.

You might think all welded pipes are the same, but the method matters. Using a general term like "ERW" without understanding the details can lead to receiving pipes with weak seams that crack during installation. ERW stands for Electric Resistance Welding. It is a process where we roll a steel plate into a cylinder and use electric current to heat the edges. The resistance of the steel generates heat, and we press the edges together to form a bond without using any extra filler metal.

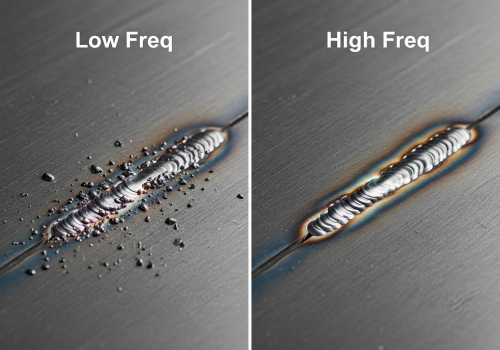

I want to dive deeper into this because it is the foundation of our topic. ERW is not just one single method. It is a family of methods. In the past, this process often used low-frequency current. When the current is low (like 50 Hz or 60 Hz), the heat spreads out widely. This creates a wide "Heat Affected Zone" or HAZ. In my experience supplying pipes to over 100 countries, I have seen standard ERW pipes used mostly for low-pressure applications. We often supply these for water pipes, wire casings, or basic structural columns. The process is very efficient. We take a flat strip of steel, roll it, and weld it in one pass. The seam runs along the length of the pipe. However, the "old style" low-frequency ERW had issues. The weld was sometimes not consistent. The heat would go too deep or not deep enough. This is why, for many years, engineers preferred seamless pipes for critical jobs. But technology has changed. Today, when we talk about ERW in a modern factory like ours, we are usually talking about a much improved process. But technically, ERW still includes those older, low-frequency methods. This is why you need to be careful with your specs. You need to know if your manufacturer is using old technology or the new standard.

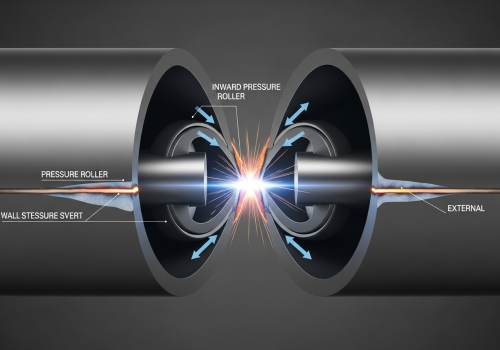

Pipeline failures cost millions and damage the environment. If you use a pipe with a brittle weld in an oil line, you are taking a massive risk that could destroy your company's reputation. HFW stands for High-Frequency Welding. It is a specific type of ERW process where the welding current frequency is very high, usually above 70 kHz. This high speed concentrates the heat instantly at the very edge of the steel.

Let me explain why this specific technology changed the industry. HFW is not a different pipe from ERW; it is the evolution of ERW. In our production bases, we use HFW because of two physical laws: the "skin effect" and the "proximity effect." When we run electricity at a very high frequency (often between 100 kHz and 600 kHz), the current does not want to flow through the whole body of the steel. It wants to travel only on the "skin" or the surface. This is the skin effect. Also, the proximity effect means the current focuses right where the two edges of the pipe meet. Why does this matter to you? It means we can heat the steel edges to a plastic state in a fraction of a second. We do not heat up the rest of the pipe. The Heat Affected Zone (HAZ) is very narrow. When we squeeze the edges together, it creates a forged weld that is incredibly strong. In the oil and gas industry, this is non-negotiable. For example, the API 5L standard is the bible for line pipes. If you need a PSL2 pipe (which is the higher specification level for gas and oil), the standard mandates the use of HFW. You cannot use low-frequency ERW. This protects the pipeline from stress corrosion cracking. At Centerway Steel, we ensure our HFW pipes meet these strict criteria so our clients in the Middle East and Europe can sleep soundly.

You need to justify your purchasing decision to your engineers. If you cannot clearly list the technical differences between general ERW and HFW, you cannot prove that you have sourced the best value for the project. When analyzing hfw vs erw pipe, the key distinction is the quality of the weld seam and the frequency of the current used. HFW offers a tighter, stronger weld structure compared to the broader, potentially weaker weld of older ERW methods.

I encounter this question almost every week from EPC companies. They ask, "Is HFW really different?" The answer is yes, and here is how I break it down for them. First, look at the frequency. As I mentioned, standard or "old" ERW operates at low power frequencies (50-60 Hz). HFW operates at radio frequencies (100-600 kHz). This is a massive difference in energy behavior. Second, look at the weld seam quality. In low-frequency ERW, the weld can suffer from a "cold weld" or "lack of fusion" because the heat is slow. In HFW, the heat is intense and focused. This squeezes out impurities and oxides during the forging pressure. Here is a simple table I use to help my clients understand:

| Feature | Low-Frequency ERW (General) | HFW (High-Frequency ERW) |

|---|---|---|

| Current Frequency | 50 - 60 Hz | 100 kHz - 600 kHz |

| Heating Method | Contact resistance (mostly) | Induction or Contact |

| Heat Affected Zone | Wide and broad | Narrow and concentrated |

| Weld Quality | Lower toughness, risk of defects | High toughness, better grain structure |

| Main Application | Water, scaffolding, structural piling | Oil & Gas pipelines, high-pressure flow |

| API 5L Status | Allowed for PSL1 only | Required for PSL2 |

When you look at hfw vs erw pipe, remember that HFW is the premium version. It is what we supply to major companies like CNPC and Shell. If you are buying for a critical project, you must specify HFW. However, if you are just building a fence or a water drain, standard ERW is cheaper and totally fine. We supply both, but my job is to make sure you use the right one.

We also treat the HFW seam with heat treatment (annealing) after welding. This removes the stress from the weld area. This makes the pipe behave like a seamless structure. This is why HFW is now competing with seamless pipes in many markets. It is cost-effective and reliable.

To summarize, ERW is the broad method, while HFW is the high-frequency advancement used for critical lines. For oil and gas, always choose HFW to ensure safety and compliance.