The 280mm SSAW steel pipe (Spiral Submerged Arc Welded steel pipe) is a high-strength, large-diameter welded pipe widely used in oil and gas transportation, water pipelines, and structural applications. Its unique spiral seam design provides excellent pressure resistance and durability, making it ideal for demanding industrial environments.

This article explores the key features, benefits, and production process of 280mm SSAW steel pipe, helping you understand why it’s a preferred choice for large-scale pipeline projects.

The 280mm SSAW steel pipe is manufactured by spirally welding hot-rolled steel coils using the submerged arc welding (SAW) process. The "280mm" refers to its outer diameter, making it suitable for medium to large-scale pipeline systems.

· Spiral seam design – Enhances structural strength and flexibility.

· High-pressure resistance – Ideal for oil, gas, and water transmission.

· Cost-effective – More economical than seamless pipes for large diameters.

The spiral welding technique distributes stress evenly, reducing weak points and improving load-bearing capacity.

The 280mm SSAW steel pipe can be produced in long continuous sections, minimizing joints and leakage risks in pipelines.

With proper coatings (like 3PE anti-corrosion treatment), it withstands harsh environments, including underground and underwater applications.

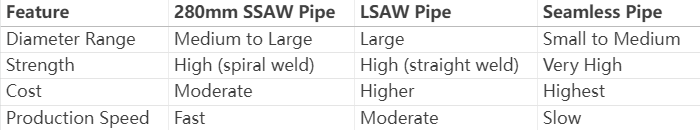

Compared to LSAW (Longitudinal SAW) or seamless pipes, 280mm SSAW steel pipe offers a better balance of performance and affordability.

The production involves several critical steps:

· Hot-rolled steel coils are unrolled and leveled.

· Edge trimming ensures uniform width for welding.

· The strip is spirally bent into a pipe shape.

· Submerged arc welding (SAW) fuses the seam under a flux layer for high-quality welds.

· The pipe passes through rollers to achieve the precise 280mm diameter.

· Straightening ensures dimensional accuracy.

· Ultrasonic testing (UT), X-ray inspection, and hydrostatic tests verify weld integrity.

· Surface coatings (e.g., galvanization or epoxy) are applied for corrosion protection.

· Oil & Gas Pipelines – Transporting crude oil and natural gas over long distances.

· Water Supply Systems – Municipal and industrial water distribution.

· Structural Uses – Piling, bridge construction, and support columns.

· Mining & Slurry Transport – Handling abrasive materials efficiently.

For projects requiring high strength, large diameter, and cost efficiency, the 280mm SSAW steel pipe is an optimal choice.

The 280mm SSAW steel pipe is a versatile, high-performance solution for industrial and infrastructure projects. Its spiral welding technology ensures durability, while its cost-effectiveness makes it a preferred option for large-diameter pipelines.

When selecting steel pipes for your next project, consider the 280mm SSAW steel pipe for reliable performance and long-term value.