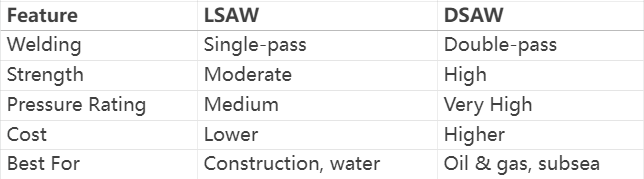

When choosing between LSAW and DSAW steel pipes, understanding their differences is crucial for selecting the right pipe for your project. Both are manufactured using the submerged arc welding (SAW) process, but their structural integrity, applications, and performance vary significantly. In this guide, we’ll break down the dsaw vs lsaw debate to help you make an informed decision.

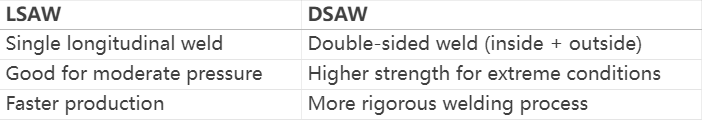

· Manufactured with a single longitudinal weld along the seam.

· Formed using UOE (U-ing, O-ing, Expansion) or JCO (J-ing, C-ing, O-ing) processes.

· Ideal for structural, piling, and medium-pressure pipelines.

· Feature dual welding (inside and outside) for enhanced strength.

· Produced via similar forming methods (UOE/JCO) but with double-pass welding.

· Preferred for high-pressure oil & gas pipelines, subsea applications, and corrosive environments.

Why it matters:

· DSAW pipes are stronger due to dual welding, making them ideal for high-stress applications.

· LSAW pipes are cost-effective for general construction and low-to-medium pressure uses.

Key Takeaway:

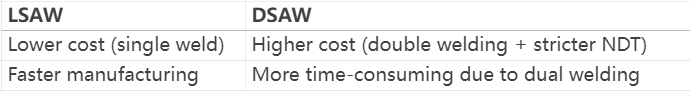

· DSAW vs LSAW pipe selection depends on pressure, environment, and budget.

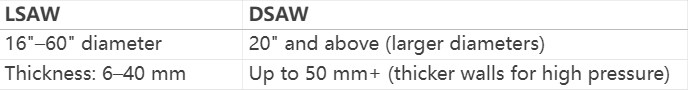

Why it matters:

· DSAW pipes handle higher pressure and harsher conditions due to thicker walls.

· LSAW pipes are more versatile for standard construction needs.

Best choice?

· Budget-friendly option? → LSAW

· Critical high-pressure project? → DSAW

Both LSAW and DSAW steel pipes comply with:

· API 5L (Oil & gas pipelines)

· ASTM A252 (Structural pipes)

· EN 10219 (European welding standards)

However, DSAW is often mandatory for extreme conditions (e.g., deepwater, Arctic pipelines).

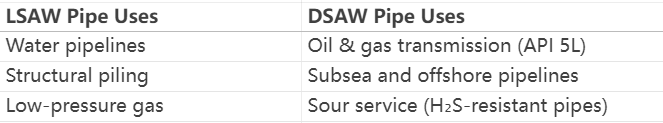

✅ Cost efficiency is a priority.

✅ The application involves water, low-pressure gas, or structural uses.

✅ High-pressure resistance is required (e.g., oil & gas).

✅ The environment is corrosive or subsea.

✅ Long-term durability is critical.

The dsaw vs lsaw debate comes down to application requirements. While LSAW pipes are economical for general use, DSAW pipes provide unmatched reliability for high-pressure and corrosive environments.

Need expert guidance? Contact our specialists today to determine whether LSAW vs DSAW pipe is the optimal solution for your project requirements!