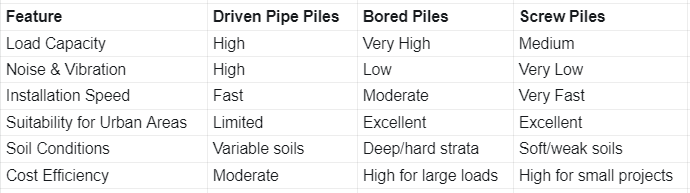

In modern foundation engineering, pipe and piling play a critical role in transferring structural loads to stable soil or rock layers. Selecting the right piling method is essential for ensuring stability, cost-effectiveness, and construction efficiency. This article compares three of the most commonly used methods—driven piles, bored piles, and screw piles—highlighting their working principles, advantages, limitations, and typical applications.

Driven piles are prefabricated steel, concrete, or timber pipes hammered into the ground using impact hammers or vibratory drivers. The pile displacement compacts surrounding soil, increasing bearing capacity.

· High load capacity: Soil densification improves structural stability.

· Immediate strength: No curing time is required.

· Quality control: Factory-produced piles ensure consistency.

· Noise and vibration: May not be suitable in urban or sensitive environments.

· Ground obstructions: Hard layers or boulders can cause pile damage.

Driven pipe piles are ideal for bridges, marine structures, and large industrial projects where soil conditions are variable and high bearing capacity is needed.

Bored piles are formed by drilling a hole into the ground, placing reinforcement cages, and filling the hole with concrete.

· Minimal vibration: Suitable for construction near existing buildings.

· Large diameters possible: Useful for projects requiring very high load capacities.

· Flexible depth: Can be drilled to penetrate deep, hard strata.

· Slower installation: Drilling and concreting take more time.

· Soil stability issues: Requires casing or drilling fluid to prevent collapse.

· Quality variation: On-site concreting introduces potential defects.

Bored piles are commonly used in urban foundations, high-rise buildings, and infrastructure projects where noise and vibration must be minimized.

Screw piles are steel shafts with helical blades screwed into the soil using hydraulic torque motors. The installation process displaces minimal soil, creating little disturbance.

· Quick installation: No curing time, immediate load transfer.

· Low noise and vibration: Ideal for sensitive environments.

· Reusability: Piles can be unscrewed and reused.

· Depth limitation: Hard layers or dense gravel can restrict installation.

· Lower load capacity: Typically suited for light to medium loads.

Screw piles are widely used in residential housing, solar farms, temporary structures, and areas with weak or soft soils.

Each piling method offers unique strengths, and the choice depends on project scale, soil conditions, and environmental constraints. Pipe and piling solutions must be carefully designed to balance cost, performance, and sustainability.

· Driven pipe piles deliver high capacity and durability but create noise and vibration.

· Bored piles provide excellent performance in urban areas but require longer installation times.

· Screw piles offer speed, versatility, and minimal disturbance, making them suitable for smaller or temporary projects.

By understanding the distinctions among these methods, engineers and contractors can select the most effective foundation solution for their specific project. Ultimately, the right pipe and piling approach ensures long-term safety, stability, and efficiency in construction.

If you are looking for high-quality piling pipe, feel free to contact us. Our team will help you find the most suitable products for your project, ensuring both technical performance and cost-effectiveness.