When it comes to selecting the right type of steel pipe for your pipeline projects, understanding the difference between LSAW and HSAW steel pipes is crucial. These pipes are prevalently used in the oil, gas, and water industries, but each type has distinct features and applications. This article delves into these differences to guide your selection process effectively.

· LSAW Steel Pipe: LSAW stands for Longitudinal Submerged Arc Welding. These pipes are manufactured by bending individual steel plates into a U-shape and welding the edges longitudinally. This straight seam formation provides robust structural integrity.

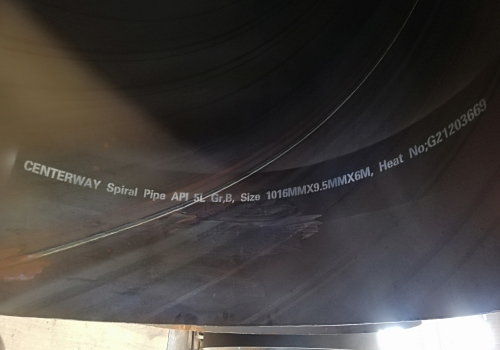

· HSAW Steel Pipe: HSAW stands for Helical Submerged Arc Welding, often known as spiral welding. These pipes are created by spirally wrapping steel strips and welding the edges, forming a continuous helical seam. This method allows for the production of larger diameters.

Formation: U-shape bending.

Welding: Single, straight longitudinal seam.

Materials: Made from flat steel plates.

Applications: Ideal for oil and gas transportation.

Formation: Helical winding.

Welding: Continuous spiral seam.

Materials: Made from coiled steel strips.

Applications: Suitable for water transmission and large structural projects.

LSAW Pipes: Best for diameters ranging from 16" to 60". These are well-suited for projects demanding high pressure and structural strength.

HSAW Pipes: Suitable for diameters over 140". These are preferred for larger scale projects where cost-effectiveness and flexibility are priorities.

LSAW Pipe Costs: Generally, LSAW pipes are more expensive due to the complexity of their manufacturing process and the superior strength of their longitudinal welds.

Quality Assurance: Requires rigorous testing methods like radiographic, ultrasonic, and hydrostatic testing.

HSAW Pipe Costs: More budget-friendly due to their simpler production process.

Considerations: Longer spiral welds can result in marginally lower strength and potential welding defects.

Your project needs will significantly influence whether you choose LSAW or HSAW pipes. Consider factors like cost constraints, required pipe diameters, and the nature of the fluid being transported.

| Feature | LSAW Steel Pipe | HSAW Steel Pipe |

|---|---|---|

| Seam Formation | Longitudinal | Spiral |

| Diameter Range | 16" to 60" | Over 140" |

| Cost | Higher | Lower |

| Application | Oil and gas pipelines | Water transmission, structural |

| Strength | Higher strength; less prone to defects | Prone to mild defects in longer weld |

Both LSAW and HSAW steel pipes have their unique strengths and applications. Your choice depends on the specific requirements of your project. Whether you need high-strength longitudinal pipes or cost-effective spiral pipes, we provide a comprehensive selection of LSAW steel pipe and HSAW steel pipe products tailored to meet your needs. Contact us today for detailed information and assistance in choosing the right product for your pipeline project.