Finding reliable large-diameter pipes for heavy-duty projects creates massive stress for procurement managers. Poor quality leads to project delays and safety hazards, but understanding LSAW specifications solves your sourcing headaches instantly. China LSAW steel pipe (Longitudinal Submerged Arc Welding) is the top choice for large-scale energy and construction infrastructure. It uses JCOE forming technology to produce diameters from 406mm to 1620mm with thick walls, offering superior high-pressure resistance and cost efficiency compared to seamless alternatives.

I remember when I first started in this industry back in the 90s. The terminology for steel pipes was confusing, and picking the wrong type could ruin a budget. Today, I want to make sure you have the clear facts. I will explain exactly what this pipe is and how we make it.

Many buyers confuse LSAW with other welding types like SSAW, risking structural failure in high-stress zones. Using the wrong pipe kills budgets, so let's clarify the technology immediately. LSAW stands for Longitudinal Submerged Arc Welding. Manufacturers of china lsaw steel pipe primarily use JCOE forming, which allows for a wider range of diameters and wall thicknesses than older UOE methods, offering flexibility for custom heavy-industry needs.

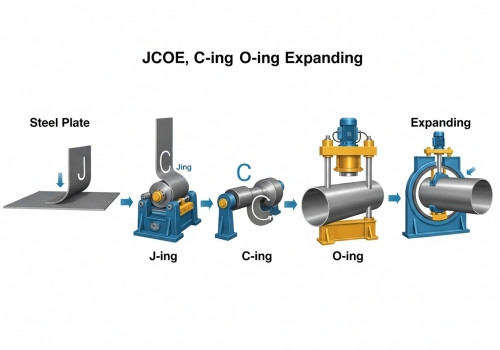

To really understand the value of this product, we need to look at how we shape the metal. The term "JCOE" describes the process of bending the steel plate. It is not done all at once. First, we press the plate into a "J" shape. Then, we press it again to make a "C" shape. Finally, we press it into an "O" shape before welding. The "E" stands for Expansion, which I will explain later. This method is different from UOE technology. UOE is faster but very expensive to set up and less flexible. In China, we prefer JCOE because we can change sizes quickly for you. If you need a pipe with an outer diameter (OD) of 1400mm today and 900mm tomorrow, JCOE handles this easily. Here is a comparison of why we use this technology:

| Feature | UOE Method | JCOE Method (Our Focus) |

|---|---|---|

| Production Speed | Very Fast | Moderate |

| Size Flexibility | Low (Fixed sizes) | High (Custom sizes) |

| Residual Stress | Higher | Lower (Better for safety) |

| Main Usage | Mass production | Custom, High-quality projects |

A lack of visibility into the factory floor breeds distrust in international suppliers. Blind trust causes anxiety, so we must examine every step of the production line to ensure safety. The manufacturing process is a 12-step cycle that turns a raw steel plate into a finished pipeline component. Key steps include edge milling, pre-welding, internal and external submerged arc welding, and mechanical expansion to ensure the china lsaw steel pipe meets strict API 5L standards.

I want to walk you through our factory floor. It is important to know that we do not just roll steel; we engineer it. The process is strict.

1. Plate Probe & Milling: It starts with the raw material. We use ultrasound to check the flat plate before we even touch it. If the plate has a crack, we reject it. Then, we mill the edges. This means we cut the sides of the plate to be perfectly straight and parallel. This prepares the metal for a strong weld. 2. Forming and Pre-welding: This is the JCO process I mentioned earlier. Once the pipe is in an "O" shape, we do a pre-weld. This is a quick weld to hold the shape together. We use Gas Metal Arc Welding (MAG) for this. It acts like a tack weld but is continuous.

3. The Major Welds: Now comes the heavy work. We perform the Inside Weld first using multi-wire submerged arc welding. Then we do the Outside Weld. This "submerged" technique means the arc is covered by flux, preventing oxidation. It creates a very deep, strong bond.

4. Expansion and Testing: This is the most critical part for an EPC manager like you. We use a mechanical expander. We push a die inside the pipe to expand it slightly. Why? Two reasons. First, it makes the pipe perfectly round. Second, and most importantly, it relieves the internal stress of the steel. A pipe with low internal stress is safer under high pressure. After this, we do the hydraulic test. We fill the pipe with water and pressurize it higher than your working pressure. We also use X-rays to look inside the weld seam again. Finally, we inspect the ends and chamfer them so they are ready for you to weld on-site.

Ignoring technical specs leads to catastrophic leaks in high-pressure lines or structural collapse. You cannot afford a burst pipe, so knowing the required features and appropriate applications is mandatory for your project's success. These pipes feature high-pressure resistance, low-temperature resilience, and large diameters suited for harsh environments. They are widely used in oil and gas transmission, offshore piling, and district heating, backed by rigorous tests like the Drop Weight Tear (DWT) and impact tests.

When you buy from us, you get more than just a round piece of metal. You get a product designed for extreme conditions. One of the main features of our LSAW pipe is the ability to withstand low temperatures. This is vital for projects in places like Russia or Northern Europe. We perform an Impact Test and a Drop Weight Tear (DWT) test to ensure the steel does not become brittle in the cold. Main Features:

· Large Diameter: We go up to 1620mm. This is huge. It allows for massive volume transport of fluids.

· Thick Walls: Up to 60mm thickness means it can handle immense internal pressure.

· High Strength: We use high-grade steel that meets API 5L X80 standards if needed. Where to Use Them: We have exported these pipes to over 100 countries. Here is where our customers use them:

1. Oil and Gas: This is the most common use. The longitudinal seam is very reliable for long-distance pipelines.

2. Construction: We supply pipes for piling. Because LSAW pipes are straight and strong, they are perfect for port construction and bridge foundations.

3. Water Projects: Large diameter pipes are efficient for sewage and water treatment plants. We also make sure the pipe ends fit your needs. We can weld flanges or lifting eyes onto the pipe before shipping. This saves you work at the construction site. Whether you are building a platform in the sea or a pipeline in the desert, this pipe is the correct choice.

Choosing the right china lsaw steel pipe ensures project safety and budget efficiency. With our JCOE technology and rigorous testing, Centerway Steel provides the reliability your engineering team demands.