Struggling to find cost-effective large-diameter piping solutions for your construction projects? Choosing the wrong pipe type ruins budgets. Here is everything you need to know to make the right choice. Helical submerged arc welded pipes, often called SSAW pipes, are large-diameter steel tubes created by rolling steel coils into a spiral shape. We weld them using double-sided submerged arc technology. This process creates a durable, flexible, and cost-efficient solution ideal for water transport, piling, and low-pressure fluid systems.

Many people think all welded pipes are the same, but they are not. The manufacturing method changes the cost, the strength, and where you should use them. If you buy the wrong type, you might pay too much or face safety risks. Let me show you why this specific type matters to your bottom line.

You worry about weld integrity in your pipelines. Weak seams cause leaks and project delays. Understanding the unique manufacturing process helps you trust the product quality. Unlike longitudinal welding, this process uses steel coils that we unwind and form spirally. We use submerged arc welding technology, burying the arc under a special flux to prevent oxidation. This ensures a deep, consistent, and defect-free weld on both the inside and outside of the pipe.

Let's dig a little deeper into how we make these at Centerway Steel. The process starts differently than other pipes. We do not use flat steel plates. Instead, we use long strips of steel coils. This is a huge advantage for you. Why? Because by changing the angle of the helix (the spiral), we can produce pipes of very different diameters using the same width of steel strip. This makes production flexible and faster for your custom orders. During the welding, we use the "Submerged Arc" method. We feed a wire filler into the seam while covering it with a granular flux. When cold, this flux does nothing. But when heated by the arc, it melts and conducts electricity. It protects the molten steel from the air. This prevents bubbles, cracks, and rust. We weld the pipe from the inside first, then the outside. This "double-sided" welding guarantees full penetration. It is important to note a common confusion. Some people confuse these with JCOE pipes. JCOE is actually a method for making Longitudinally Submerged Arc Welded (LSAW) pipes, shaped like a J, then C, then O. Helical submerged arc welded pipes are strictly spiral. This spiral shape actually helps stop long cracks from spreading if the pipe gets damaged, making them surprisingly tough.

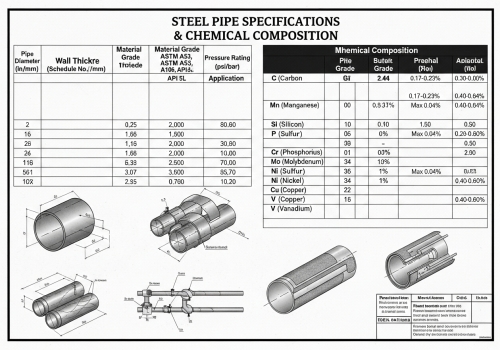

Incorrect specifications lead to immediate project failure. It is a nightmare for sourcing managers to get pipes that don't match the design. You need the right data to order correctly. The most common standard for these pipes is API 5L. These pipes come in various grades like Grade B, X42, up to X80. Knowing the chemical and tensile properties ensures the pipe can handle your project's specific pressure and environmental stress requirements without failing.

As a purchasing manager, you deal with numbers all day. When sourcing helical submerged arc welded pipes, the API 5L specification is your bible. It sets the rules for how strong the steel must be. We supply grades ranging from Grade B (standard) up to high-strength X80. Here is a simple breakdown of the chemical composition for common grades we supply. This controls weldability and strength:

| Grade | Carbon (Max %) | Manganese (Max %) | Sulfur (Max %) | Phosphorus (Max %) |

|---|---|---|---|---|

| Grade B | 0.26% | 1.20% | 0.030% | 0.030% |

| X42 | 0.26% | 1.30% | 0.030% | 0.030% |

| X52 | 0.26% | 1.40% | 0.030% | 0.030% |

| X60 | 0.26% | 1.40% | 0.030% | 0.030% |

| X70 | 0.26% | 1.65% | 0.030% | 0.030% |

And here is what matters for your engineers—the strength:

|

Grade |

Min Yield Strength (psi) |

Min Tensile Strength (psi) |

|

Grade B |

35,000 |

60,000 |

|

X42 |

42,000 |

60,000 |

|

X52 |

52,000 |

66,000 |

|

X60 |

60,000 |

75,000 |

|

X70 |

70,000 |

82,000 |

Why do we use copper coating on the filler wire? It stops the wire from rusting before we weld. It also helps conduct electricity better. We check these specs rigorously. At Centerway, we know that for a German EPC company, "almost correct" is not good enough. We ensure every pipe meets these exact numbers so your project passes inspection the first time.

Budget cuts are always looming over construction projects. You need to save money without losing quality. The choice between LSAW and Helical pipes is key to this balance. LSAW pipes use steel plates and a straight seam, making them stronger for high-pressure applications but more expensive. Helical pipes use coils and spiral welds, offering a significantly lower cost and greater size flexibility for non-critical pressure lines and structural use.

This is the question I get asked most often by my clients in Europe. "Jackie," they say, "Why should I buy helical pipes instead of longitudinal ones?" The answer is value. LSAW (Longitudinal Submerged Arc Welded) pipes are made from single heavy plates. This process is slow and the raw material is expensive. They are great for high-pressure deep-sea oil lines. But for many land-based projects, they are overkill. You are paying for performance you do not use. Helical submerged arc welded pipes are made from coils. The continuous rolling process is faster and cheaper. Also, we can make huge pipes—up to 100 inches or more—much easier than with LSAW. Here is a quick comparison to help you decide:

| Feature | LSAW (Longitudinal) | Helical (SSAW) |

|---|---|---|

| Raw Material | Steel Plate | Steel Coil |

| Weld Seam | Straight line | Spiral line |

| Production Cost | High | Low (Cost-effective) |

| Diameter Range | Limited by plate width | Very flexible (Small to Huge) |

| Primary Use | High-pressure Oil/Gas | Water, Piling, Low-pressure fluids |

Some people worry that the spiral weld is longer, so it might be weaker. Actually, the spiral geometry can handle stress very well. If a crack starts, the spiral direction often stops it from running down the whole pipe. For water projects, port construction, or structural piling, helical pipes are the smart financial choice.

Helical welded pipes offer a strong, flexible, and budget-friendly solution for water and structural projects. Choosing them over expensive alternatives ensures quality while keeping your sourcing costs low.