Spiral welded steel pipes are fundamental components in oil, gas, and water infrastructure, but improper storage often leads to rust formation. Understanding the critical difference between surface rust vs deep rust is essential for maintaining pipeline integrity and avoiding costly mistakes. This comprehensive guide provides detailed identification methods, prevention strategies, and industry standards to help you make informed decisions about your spiral welded steel pipes.

· Formation: Develops within weeks/months of outdoor exposure

· Appearance: Light orange/brown, powdery coating

· Texture: Smooth, no pitting

· Removability: Wipes off easily with cloth or light brushing

· Structural Impact: None - doesn't affect pipe integrity

· Formation: Requires 1+ years of neglect or harsh conditions

· Appearance: Dark red/brown/black with irregular patterns

· Texture: Rough, pitted surface with visible craters

· Removability: Requires aggressive sanding/sandblasting

· Structural Impact: Compromises wall thickness and strength

Key Difference in Spiral Welded Steel Pipes: Surface rust is cosmetic while deep rust threatens structural safety.

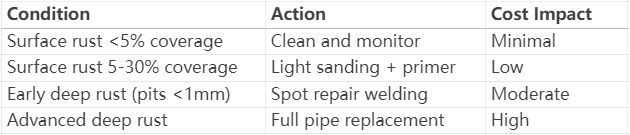

For spiral welded steel pipe users:

· Cost Savings: Avoid unnecessary replacement of pipes with harmless surface rust

· Safety Assurance: Detect dangerous deep rust before pipeline failures occur

· Quality Control: Maintain compliance with API 5L and ASTM standards

· Inventory Management: Properly assess stored pipe conditions

Common Mistake: Up to 40% of spiral pipe rejections are due to misidentified surface rust, creating millions in unnecessary costs industry-wide.

Visual Inspection Protocol

1. Color Test: Surface rust appears uniform; deep rust shows mottled colors

2. Texture Check: Run fingernail across surface - catches on deep rust pits

3. Wipe Test: Use clean white cloth - surface rust transfers color

Professional Assessment Methods

· Ultrasonic Thickness Testing: Measures remaining wall thickness

· Digital Microscopy: Examines pitting depth at 200x magnification

· Salt Spray Testing: Accelerated corrosion assessment

Pro Tip: For spiral welded steel pipes stored over 6 months, combine visual and ultrasonic testing for complete assessment.

· Apply VCI (Vapor Corrosion Inhibitor) coatings

· Store pipes on elevated racks with proper ventilation

· Use breathable protective wraps

· Implement galvanization or epoxy coatings

· Schedule biannual inspections for long-term storage

· Maintain proper humidity control in storage areas

Industry Best Practice: The American Petroleum Institute recommends protective coatings for spiral welded steel pipes stored beyond 3 months.

Decision Tree: Always measure remaining wall thickness - if below 90% of original, replacement is mandatory for pressure applications.

Spiral welded steel pipes must comply with:

· API 5L PSLO1: Allows surface rust but prohibits deep rust

· ASTM A106: Specifies maximum pit depth tolerances

· NACE SP0169: Cathodic protection standards for rust prevention

Certification Tip: Always request mill test reports showing chemical composition and original surface conditions.

Properly distinguishing between surface rust vs deep rust in spiral welded steel pipes:

· Saves 15-30% in unnecessary replacement costs

· Prevents catastrophic pipeline failures

· Extends service life by 5-10 years

· Maintains compliance with strict industry standards

Final Recommendation: To ensure optimal performance and longevity of your spiral welded steel pipes, we strongly recommend implementing a comprehensive inspection program that combines thorough visual checks with precise ultrasonic testing - particularly for pipes in long-term storage. For complete peace of mind, partner with reputable suppliers who provide proper indoor storage facilities and advanced rust prevention treatments.

If you require high-quality spiral welded steel pipes that meet the strictest industry standards, look no further. Our premium products undergo rigorous quality control and proper storage protocols to deliver exceptional performance you can rely on. We guarantee our pipes won't disappoint - offering superior corrosion resistance, certified materials, and reliable structural integrity for your most demanding applications. Contact us today for spiral welded steel pipe solutions that exceed expectations.