In the high-stakes world of oil and gas transportation, pipeline integrity isn't just important - it's everything. A single pipeline failure can result in catastrophic environmental damage, massive financial losses, and significant reputational harm. This is why industry leaders increasingly turn to SSAW pipe (Spiral Submerged Arc Welded pipe) as their go-to solution for safe, reliable, and cost-effective energy transportation.

Unlike traditional straight-seam alternatives, SSAW pipe features a distinctive spiral weld pattern created by:

· Continuously forming steel coils at an angle

· Welding the seam using submerged arc welding (SAW) technology

· Precisely controlling the spiral angle to optimize strength

This innovative manufacturing approach gives SSAW pipe several inherent advantages that make it particularly suitable for demanding oil and gas applications.

The spiral weld design of SSAW pipe provides:

· Superior stress distribution compared to straight-seam pipes

· Greater resistance to cracking under extreme pressure fluctuations

· Enhanced durability in seismic zones or unstable terrain

Industry Insight: A 2023 study by the Pipeline Research Council International found that spiral-welded pipes showed 23% better fatigue resistance in high-pressure gas transmission applications.

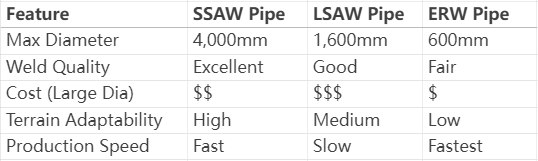

When it comes to large-diameter pipelines (24" and above), SSAW pipe offers significant advantages:

· Lower material costs: Uses narrower steel strips compared to LSAW plate requirements

· Reduced welding costs: Continuous spiral welding is more efficient than multiple straight seams

· Transportation savings: Can be manufactured closer to project sites due to flexible production

Case Study: The East-West Gas Pipeline project saved an estimated $18 million in material costs by using SSAW pipe for its 56" diameter sections.

The natural flexibility of SSAW pipe makes it ideal for:

· Mountainous regions where pipeline routing requires curvature

· Permafrost areas subject to ground movement

· River crossings and other challenging installations

Pro Tip: Many engineers specify SSAW pipe for projects with elevation changes exceeding 2% to minimize the need for expensive field bends.

Modern SSAW pipe manufacturing incorporates:

· Automated ultrasonic testing of 100% of welds

· X-ray inspection of critical joints

· Hydrostatic testing at 1.5 times operating pressure

Safety Statistic:* Pipelines using SSAW pipe have shown a 40% lower incidence of weld-related failures compared to ERW alternatives in API-reported data.

Advanced coating options for SSAW pipe include:

· 3-layer PE (Polyethylene) systems

· Fusion-bonded epoxy (FBE) coatings

· Internal cement lining for abrasive flows

Maintenance Advantage: Properly coated SSAW pipe can achieve 50+ years of service life in typical oil and gas applications.

Major projects like the Power of Siberia gas pipeline utilize SSAW pipe for its combination of strength and cost-effectiveness over thousands of kilometers.

The spiral weld's natural resistance to hoop stress makes SSAW pipe ideal for deepwater applications.

Few pipe types can match SSAW pipe's performance in extreme low-temperature environments.

Q: Can SSAW pipe be used for sour gas service?

A: Yes, with proper material selection (typically API 5L X52 or higher with HIC testing).

Q: What's the maximum pressure rating for SSAW pipe?

A: Modern SSAW pipe can be manufactured to withstand pressures exceeding 20MPa (2,900 psi).

Q: How does SSAW pipe perform in seismic zones?

A: The spiral design provides excellent flexibility, making it preferred for earthquake-prone areas.

As the oil and gas industry faces increasing pressure to deliver projects on time and under budget while maintaining the highest safety standards, SSAW pipe emerges as the clear technical and economic solution for modern pipeline challenges. Its unique combination of strength, adaptability, and cost efficiency ensures that SSAW pipe will remain the backbone of energy infrastructure projects worldwide for decades to come.

For project planners and engineers, the message is clear: when pipeline performance matters, SSAW pipe delivers where it counts.