Finding the right steel pipe specifications can be confusing and stressful for project managers. You do not want to risk structural failure by choosing the wrong welding method. I will explain exactly what this pipe is and why it matters. A dsaw pipe stands for Double Submerged Arc Welded pipe. It is a steel pipe manufactured by welding both the inside and outside seams simultaneously or sequentially. This double-sided technique guarantees 100% penetration and provides superior structural strength compared to single-sided welding. It is the top choice for high-pressure oil lines and heavy construction piling.

Many people in the construction industry get confused by all the acronyms we use. You might see terms like ERW, LSAW, or SSAW on a spec sheet. However, understanding the specific technology behind the double submerged arc process is vital. It changes how the pipe handles pressure. It changes the cost. It determines the safety of your project. As a supplier since 1996, I have seen how the right choice saves millions. Now, let us look at exactly how we make these pipes.

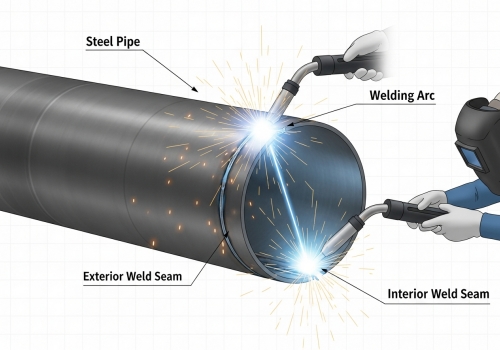

You might worry about the quality of the weld seam in large pipes. A weak seam is the most common cause of pipeline leaks or structural collapse. We solve this through a rigorous manufacturing process. The production process involves forming the steel plate or coil into a cylinder first. Then, we weld the internal seam followed by the external seam using arc technology. This "double" action ensures the weld fuses completely through the metal thickness. It eliminates defects and creates a bond stronger than the base metal itself.

I want to take you inside the factory to understand this better. At Centerway Steel, we see this process every day. The "D" in DSAW is the most important part. It stands for "Double." In older or cheaper methods, manufacturers might only weld from one side. That leaves room for air pockets or weak spots at the root of the weld. With a dsaw pipe, we use a very specific flow.

1. Forming: We press the steel plate (for straight seams) or uncoil steel strips (for spiral seams) into the desired shape.

2. Internal Welding: A welding boom goes inside the pipe. It lays down the first pass of the weld.

3. External Welding: The pipe rotates or moves, and a second welding head lays a bead on the outside. This outer weld overlaps the inner weld. This overlap is critical. It ensures there is no "un-welded" material left in the middle. We call this "full penetration." For thick walls, this is the only way to guarantee safety. Also, the "Submerged Arc" part means the electric arc is buried under a layer of flux powder. This protects the hot metal from air, preventing rust or bubbles during the cooling phase. This process allows us to make pipes with very thick walls and large diameters that still hold immense pressure.

Purchase orders often have conflicting abbreviations that give procurement managers headaches. You need to be 100% sure of what you are buying. Clarity here prevents expensive returns and project delays. DSAW refers to the welding method (Double Submerged Arc Welding), while LSAW (Longitudinal) and SSAW (Spiral) refer to the direction of the weld seam. In reality, most high-quality LSAW and SSAW pipes are also DSAW pipes. Understanding this distinction helps you navigate technical standards and talk confidently with engineers.

This is the most common question I get from my clients in Germany and around the world. They ask, "Should I buy LSAW or DSAW?" I tell them it is often the same product, just described differently. Let me break this down using my critical thinking approach. We need to separate the "Method" from the "Shape."

· LSAW describes WHERE the seam is (Longitudinal/Straight).

· SSAW describes WHERE the seam is (Spiral/Helical). Here is a simple table to help you visualize the relationship:

| Term | Full Name | Focus | Relationship to DSAW |

|---|---|---|---|

| DSAW | Double Submerged Arc Welding | The Technique | This is the parent technology. |

| LSAW | Longitudinal Submerged Arc Welding | The Geometry | Most LSAW pipes use the DSAW technique. |

| SSAW | Spiral Submerged Arc Welding | The Geometry | All SSAW pipes utilize the DSAW technique. |

You have high standards for your projects and cannot afford material failure. Choosing a pipe that cannot handle the environment puts your reputation at risk. You need proven reliability. DSAW pipe is dominant in industries requiring high load-bearing capacity and pressure resistance. We supply these pipes for oil and gas transmission, offshore platforms, and structural piling for skyscrapers. Their ability to withstand high stress makes them ideal for wind tower construction and complex water transmission systems in difficult terrain.

We have supplied these products since 1996, so I have seen them used in almost every heavy industry imaginable. The application usually dictates the wall thickness and the steel grade we use. Because the DSAW process allows for simultaneous testing and welding, the reliability is very high. Here are the main areas where our global clients use these pipes:

1. Oil and Gas Industry: This is the biggest user. The pipes transport crude oil and natural gas over long distances. The double weld prevents leaks even under high internal pressure. We have worked with companies like CNPC and Shell who demand this quality.

2. Construction and Piling: Look at any new port or bridge. The huge steel tubes driven into the seabed are usually DSAW pipes. They act as the legs for the structure. They must support thousands of tons.

3. Water Projects: For large city water mains or sewage, you need large diameters. Spiral DSAW pipes are perfect here because we can make them very wide (up to 3000mm or more) efficiently.

4. Energy and Mining: In wind power, the towers are made of rolled DSAW sections. In mining, slurry pipelines use these pipes because the smooth internal weld reduces friction and wear from the rocks and mud. We always check the environment. If it is corrosive, like the ocean, we add special coatings. But the core strength comes from that double arc weld.

Sending an incomplete inquiry leads to wrong quotes and wasted time. You want to get the price right the first time. I will show you the checklist seasoned buyers use. To source the correct pipe, you must provide the Outer Diameter (OD), Wall Thickness (WT), and Length. You must also specify the steel grade (like X52 or X70) and the execution standard (such as API 5L or ASTM A252). Mentioning "DSAW" specifically ensures you get the double-sided weld quality you expect.

As a purchasing manager, you know that "steel pipe" is too vague. When you contact a supplier like Centerway Steel, the more details you give, the faster we can help. I remember a project where a client forgot to specify the weld type. They almost got a single-side welded pipe for a high-pressure line. We caught the error in time, but it was close. Here is the checklist I recommend for your inquiries:

· Length: Do you need random lengths (6-12 meters) or fixed lengths (exactly 11.8 meters)? This affects shipping.

· Standard: This is the rule book. API 5L is for oil/gas. ASTM A252 is for piling. ASTM A53 is for general fluid.

· Coating: Do you need 3LPE, FBE, or just black paint? Bare steel rusts fast.

· End Finish: Bevelled ends for welding or plain ends? At Centerway, we integrate production and inventory. We can handle large diameters, heavy thickness, and ultra-long pieces. We inspect everything with SGS or TUV standards. When you send us these details, we can quickly check our stock or schedule production. It makes your job easier and ensures your project stays on schedule.

DSAW pipe offers superior strength and reliability through its double-sided welding process. By understanding the manufacturing, clear terminology, and correct specifications, you ensure safety and efficiency for your heavy construction projects.