Finding the right steel pipe supplier often feels like walking a tightrope between cost and quality. You worry about weld defects, delayed timelines, and specifications that do not match your project needs. I understand this pressure because I have helped procurement managers navigate these challenges since 1996. The HFW pipe manufacturing process stands for High-Frequency Welded pipe production. It uses a high-frequency current, usually over 70 kHz (or 100 kHz for EN standards), to heat steel edges for welding. This method creates a strong, precise bond without filler material, making it ideal for oil, gas, and construction projects.

Many people think all welded pipes are the same, but the specific technology matters immensely for the safety of your pipeline. If you stop reading now, you might miss the critical details that separate a pipe that lasts 20 years from one that fails in five.

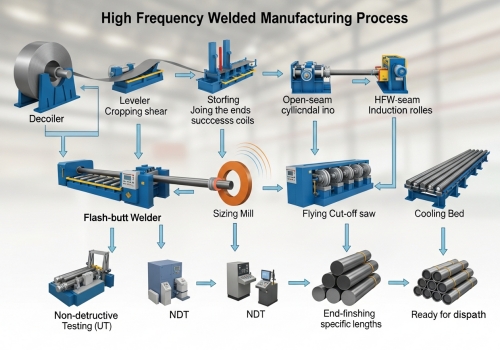

You cannot afford to buy products blindly without understanding how they are made. If you do not know the critical control points in production, you cannot effectively audit your suppliers or guarantee project safety. The manufacturing process of HFW steel pipe involves uncoiling steel strips, forming them into a cylinder, and welding the edges using high-frequency current. Key steps include weld seam annealing, sizing for dimensional accuracy, and rigorous non-destructive testing to ensure no defects exist before the final coating.

I want to take you deeper into the factory floor. When I walk through our Centerway Steel production base, the first thing I notice is the precision of the hfw pipe manufacturing process. It is not just about bending steel; it is about controlling energy. First, we start with Raw Material Preparation. We select high-grade steel coils. This is the foundation. If the coil has poor chemistry, the weld will fail. Next is Forming. We use a specialized forming machine that gradually bends the flat steel strip into a round pipe blank. This must be done gently to avoid stress on the metal. Then comes the most important part: High-Frequency Welding. Unlike older methods, we use a current (often exceeding 70 kHz or even 100 kHz depending on if we are following API 5L or EN 10217-2 standards) to heat the edges. We do not use any filler metal. The edges heat up instantly, and rollers squeeze them together. This extrusion forces impurities out and creates a solid forged bond. After welding, the pipe goes through Weld Seam Treatment. We remove the internal and external "flash" or beads to make the surface smooth. But we don't stop there. The welding heat changes the metal structure, so we perform Online Seam Annealing. We reheat the weld area to normalize the grain structure. This prevents the weld from being brittle. Finally, the pipe goes through Sizing and NDT (Non-Destructive Testing). We use ultrasonic or X-ray tests to look inside the weld. If there is a flaw, the machine marks it immediately. Here is a simple breakdown of the process and what we check at each stage:

| Process Step | Action Taken | Quality Checkpoint |

|---|---|---|

| Uncoiling | Flattening the steel coil | Check surface for scratches or rust |

| Forming | Bending strip to cylinder | Monitor edge alignment |

| Welding | HF Current heating & Squeeze | Monitor heat input and squeeze pressure |

| Seam Annealing | Reheating the weld zone | Ensure correct temperature to restore toughness |

| Sizing | Reducing diameter slightly | Check Roundness and OD tolerance |

| NDT Inspection | Ultrasonic/Eddy Current scan | Detect hidden cracks or lack of fusion |

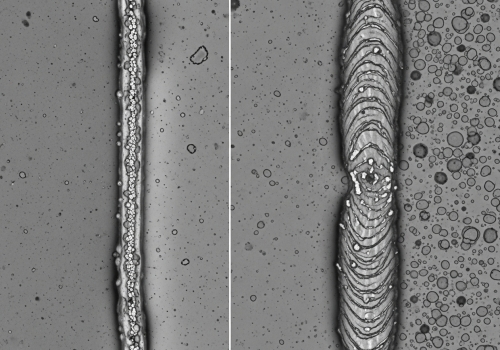

Using outdated welding methods is a hidden risk that can destroy your project budget later. If you choose pipes made with low-frequency techniques, you risk weld cracks and corrosion that might not appear until the pipes are underground. The HFW process offers superior weld quality because the heat is concentrated strictly on the edges, creating a narrow Heat Affected Zone (HAZ). This results in higher production efficiency, lower costs due to no filler materials, and strength that is virtually identical to the base metal.

In my experience dealing with global EPC companies, I often hear the question: "Why should I choose HFW over other types?" The answer lies in the physics of the hfw pipe manufacturing process. The magic happens due to two electrical effects: the Skin Effect and the Proximity Effect. In simple terms, the high-frequency current concentrates entirely on the surface of the conductor (the pipe edges). It does not waste energy heating the rest of the pipe body. This means the heat is intense and focused. Because the heat is so localized, the Heat Affected Zone (HAZ)—the area where the metal properties change due to heat—is very narrow. A narrow HAZ is excellent because it means less of the pipe has been weakened by thermal stress. Another major advantage is consistency. Because the process is highly automated, we can control the welding temperature within a very tight range. This leads to stable quality. As a purchasing manager, you know that consistency is key. You need the first pipe and the thousandth pipe to be exactly the same. Furthermore, let's talk about cost. HFW does not require welding wire, flux, or shielding gas. These are consumables that add up in cost for other methods like Submerged Arc Welding (SAW). By removing these consumables, we lower the production cost, and we pass those savings on to you. At Centerway Steel, we see HFW as the perfect balance. It gives you the high strength needed for pressure applications but at a price point that keeps your project within budget. It is efficient, clean, and reliable.

Using the wrong standard for your pipe application is a legal and safety nightmare waiting to happen. You need to know exactly which international specifications align with HFW production to ensure your project complies with engineering requirements. HFW steel pipes are widely used in oil and gas transportation, urban heating networks, and structural piling due to their durability. They comply with major standards like API 5L, ASTM A53, and EN 10217-2, making them suitable for both high-pressure fluids and structural loads. I remember a client from a construction firm in Europe. He was confused about whether he could use HFW pipes for a structural project that also carried low-pressure water. He was used to seamless pipes but wanted to save money. I explained that the hfw pipe manufacturing process meets rigorous international standards, making it a safe and economical switch. At Centerway Steel, we supply pipes that meet a vast array of global standards. For the oil and gas sector, API 5L is the bible. It dictates strict requirements for line pipe. For general liquid and gas transport, ASTM A53 is very common. However, since you are operating in the European market, you likely encounter EN standards.

· EN 10210 covers hot-finished structural hollow sections. We can produce HFW pipes in a wide size range to fit these standards. Typically, our Outer Diameter (OD) capabilities range from 73 mm to 660.4 mm. For wall thickness, we can handle from 3 mm up to 22 mm. The applications are diverse. We supply these pipes for Transportation Pipelines (oil, gas, water), District Heating, and Structural Engineering (bridges, stadium roofs, piling). Because the weld is forged and tested, it can withstand significant internal pressure and external physical loads. By integrating production and sales, Centerway guarantees that whether you need a pipe for a skyscraper in Berlin or a pipeline in the Middle East, the standard will be met exactly. We share China-made quality with the world, ensuring you get the right spec every time.

The HFW pipe manufacturing process delivers high-strength, precise, and cost-effective pipes suitable for critical oil, gas, and structural projects. At Centerway Steel, we ensure strict adherence to global standards like API and EN to support your project's success.