You need to buy steel pipes for a big project. But there are so many acronyms, like ERW, LSAW, and HFW. It is confusing and stressful. If you choose the wrong type, you might waste money or risk safety. I will explain the HFW pipe meaning simply to help you make the right choice. The HFW pipe meaning refers to steel pipes produced using "High Frequency Welding." This is a method where high-frequency electrical current creates heat to melt the edges of the steel coil. They join together without any extra filler material. This creates a very strong and precise bond for your pipelines.

Many people in the industry get mixed up between normal ERW pipes and HFW pipes. They look similar. However, the performance is very different. I want to show you exactly why HFW is the "game changer" mentioned in many articles. I will break this down so you can buy with confidence.

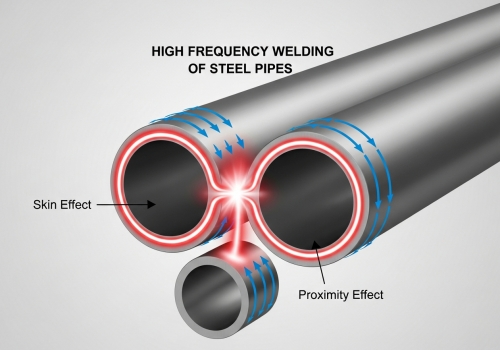

You want pipes that are strong and consistent. But old welding methods often leave weak spots. This scares many engineers. I will show you how the HFW process solves this problem completely. The core of the HFW pipe meaning lies in the physics of how it is made. In our factory at Centerway Steel, we use alternating current (AC). This current ranges from 70 kHz to 450 kHz. This is very high speed. Because the frequency is so high, two things happen. We call them the "skin effect" and the "proximity effect." The current concentrates only on the very surface of the steel strip edges. It heats up very fast. It does not heat the whole pipe body. Then, squeeze rolls press the edges together. They fuse instantly. We do not add any outside metal. It is a solid-state forge weld. This is different from older low-frequency welding. Low-frequency welding heats a wider area and makes a bigger, softer weld. That can be weak. HFW makes a narrow, hard, and clean weld. This is why HFW pipes are much stronger and have better dimensional accuracy than older types.

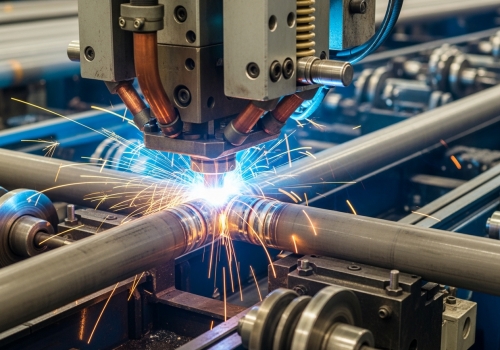

To understand this fully, we must look at the production line steps. I have seen this process every day since 1996. It is fascinating. First, we uncoil a long steel strip. We level it and cut the ends to make them square. Then, a forming machine bends the flat strip into a round tube shape. This is done at room temperature. Next comes the welding. This is the critical part. An induction coil surrounds the open tube. It induces the high-frequency current I mentioned earlier. The edges melt. The squeeze rolls apply pressure. This pressure forces out impurities and oxides from the weld zone. This leaves a very clean bond. After welding, there is a "flash" or excess metal on the inside and outside. We trim this off immediately with carbide tools while it is still hot. This makes the surface smooth. But we are not done. The weld area is now hard and stressed. We must treat it. We use a process called Seam Annealing. We heat the weld area again to normalize the grain structure. This makes the weld as tough as the rest of the pipe body. If a manufacturer skips this, the pipe might crack. At Centerway Steel, we never skip this. Finally, we size the pipe to the exact diameter and cut it to length. This process is continuous and fast. This speed is why HFW pipes are cost-effective for your projects.

Your boss wants you to save money. But the engineers demand high quality. It feels like you cannot win. I will compare these pipes to help you find the perfect balance. HFW pipes offer the best balance between cost and performance. This answers your need for a "one-stop" solution that fits the budget. Seamless pipes are great, but they are expensive. LSAW pipes are strong, but they are slow to make. HFW sits in the sweet spot.

As a purchasing manager, you need data. You need to justify your decision to your team. I have created a table to compare HFW with other common types. This helps you understand where the HFW pipe meaning translates into real value.

| Feature | HFW Pipe (High Frequency Welded) | Seamless Pipe | LSAW Pipe (Longitudinal Submerged Arc) |

|---|---|---|---|

| Manufacturing Method | Continuous roll forming + Induction welding | Hot extrusion / piercing solid billet | Steel plate forming + Double-sided arc welding |

| Cost | Low to Medium (Best Value) | High | Medium to High |

| Production Speed | Very High | Medium | Low |

| Wall Thickness | Uniform (Very consistent) | Variable (Can be uneven) | Uniform |

| Diameter Range | Small to Medium (Usually up to 24 inch) | Small to Large | Medium to Very Large (Up to 60+ inch) |

| Surface Finish | Excellent | Rougher | Good |

| Typical Use | Oil & Gas lines, Construction, Water | High Pressure, High Temp, Critical Service | Heavy Wall, Large Diameter Oil & Gas |

From this table, you can see the advantage. If your project needs pipes under 24 inches (610mm), HFW is often the winner.

Seamless pipes have no weld. This is good for extremely high pressure. However, the wall thickness of seamless pipes can vary. It is hard to control. HFW is made from steel plate (coils). Steel plates are rolled very precisely at the steel mill. So, the wall thickness of an HFW pipe is very consistent.

LSAW uses a filler metal. It is slower to make. It is good for very thick walls or huge diameters. But for standard pipelines, it is overkill and too expensive.

At Centerway Steel, we supply all these types. But I often suggest HFW to my clients in the oil and gas sector because it saves them 20% to 30% in costs compared to seamless, with very similar performance.

You worry about compliance. If the pipes do not meet the standard, you have a big legal problem. I will list the exact standards you need to check for HFW pipes. The versatility of HFW pipes is huge. They are not just for one industry. Because of the strong weld, we can use them for high-pressure fluids. We also use them for structural columns. The HFW pipe meaning in the market is reliability across many sectors.

Let's look at where our customers actually use these pipes. This will help you see if they fit your current project. 1. Oil and Gas Transportation This is the biggest market. We follow the API 5L standard. This is the bible for line pipes. HFW pipes are used for:

· Natural gas distribution networks.

· LPG transportation. The weld must be perfect here. We use grades like X42, X52, X60, and up to X70. The "X" stands for the yield strength. 2. Construction and Structure You work in the construction industry, so this is vital for you. We use standards like ASTM A500 or EN 10219. HFW pipes are used for:

· Piling (foundation support).

· Scaffolding.

· Steel structures for airports and stadiums.

· Bridges. Because HFW pipes look good and are straight, they are great for exposed structures. 3. Water Systems For water, we often use ASTM A53. HFW pipes are strong enough to handle water hammer (pressure spikes) better than plastic. 4. District Heating In places like Germany or Northern China, we need district heating. HFW pipes carry hot water or steam. They handle the thermal expansion well. When you buy from Centerway Steel, we ensure the pipes meet these specific norms. We provide MTC (Mill Test Certificates) for every batch. This includes chemical analysis and mechanical testing. We check the yield strength, tensile strength, and impact properties. This paperwork is your safety net.

To summarize, the HFW pipe meaning is a high-precision, cost-effective steel pipe made with high-frequency current and no filler metal. It offers you great strength, uniform wall thickness, and lower costs than seamless pipes. As a purchasing manager, choosing HFW for the right application saves your company money without sacrificing quality. At Centerway Steel, we have integrated these solutions since 1996 to help you succeed.