You are likely facing a tight project deadline and difficult soil conditions. Choosing the wrong piling material right now could mean project delays, water leaks, and exploded budgets. Hot rolled steel sheet pile is generally superior for heavy marine and civil projects due to its tighter Larssen interlocks and greater drivability in hard soil. While cold rolled is cheaper, hot rolled offers better water tightness and durability for demanding engineering requirements.

In my years working with global partners at Centerway Steel, I have seen many project managers struggle with this specific decision. The choice between hot and cold rolling is not just about price; it is about the safety and longevity of your structure. I want to share my insights to help you choose the right path.

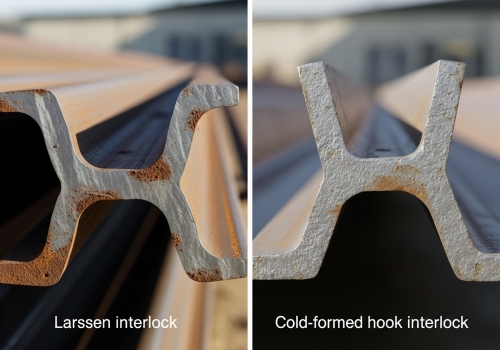

You see two piles that look similar, but their birth stories are completely different. This difference in creation dictates exactly how they will perform under extreme pressure at your site. Hot rolled piles are formed at temperatures over 1,700°F, allowing the steel to be molded into a single, dense unit. Cold rolled piles are bent at room temperature, resulting in a looser connection.

To truly understand why hot rolled steel sheet pile is often the preferred choice for engineers, we have to look at how it is made. I remember visiting our production line and feeling the intense heat coming from the billets. We take a large block of steel, heat it until it is glowing red, and pass it through rollers. Because the steel is so hot and soft, we can shape the interlock—the part that connects the piles—very precisely. This creates the famous "Larssen" interlock, which is a ball-and-socket shape. It is tight and strong because it is molded, not bent. On the other hand, cold rolled piling is made at room temperature. The manufacturer takes a coil of flat steel and runs it through machines that bend it into shape. It is like folding a piece of paper. Because they are just bending cold steel, they cannot make that tight ball-and-socket lock. Instead, they make a simple hook shape. At Centerway Steel, we have ISO 9001 and ISO 14001 certifications, so we understand that the manufacturing method changes the molecular structure of the steel. The hot rolling process makes the steel denser and tougher, which is why it can withstand being driven into hard rock without deforming.

A cheap pile is only cheap until it starts leaking water into your excavation site. Understanding the physical limitations of the interlock is vital for your project's safety and success. Hot rolled piles feature a tight ball-and-socket connection that resists water seepage effectively. Cold rolled piles use a folded hook connection that is looser, often requiring extra sealing and struggling in hard ground driving.

When you are working on a bridge foundation or a port project, water is your enemy. This is where the difference between the two types becomes very clear. I have supplied products to major oil and gas companies like CNPC and Shell, and they almost always demand high water tightness. Hot rolled steel sheet pile performs much better here. Because the interlock is tight, it naturally seals out water. Cold rolled piles have a loose connection. If you use them in water, you often have to apply expensive sealants or you risk flooding your work area. Also, think about the ground you are driving into. If the soil is soft, cold rolled might be fine. But if you have rocks or dense sand, you need power. Hot rolled piles are thicker and stronger at the corners. You can hit them hard with a hammer, and they go down straight. Cold rolled piles are thinner and have residual stress from the bending process. If you hit them too hard, the interlocks can "unzip" or the pile can twist. This is a nightmare to fix. Here is a simple table to compare them:

| Feature | Hot Rolled Sheet Pile | Cold Rolled Sheet Pile |

|---|---|---|

| Interlock Type | Ball-and-Socket (Larssen) | Bent Plate Hook |

| Water Tightness | Excellent (Naturally Tight) | Poor (Loose, needs sealant) |

| Driving in Hard Soil | Excellent (Strong, durable) | Weak (Prone to deformation) |

| Steel Density | High | Medium |

| Recycled Content | Almost 100% | Approx. 80% |

Budgets are tight in every EPC company, and cutting costs is tempting. However, looking at the upfront price tag often hides the expensive repair costs that come down the road. While cold rolled piles can be 30-40% cheaper to produce and transport, the potential for failure in difficult soil or marine environments often makes hot rolled steel sheet pile the more cost-effective long-term investment.

I admit, the price of cold rolled steel is attractive. It is usually lighter, which means you can put more on a truck, saving money on shipping. It is also faster to produce, often ready in two weeks. For temporary walls or projects with very easy soil conditions, I sometimes tell my clients that cold rolled is a fine choice. We want to be a one-stop supplier for you, so we will be honest about what you need. However, for a serious EPC contractor, the risk is usually too high. I once knew a project manager who switched to cold rolled piles to save 30% on the material budget. But when they started driving the piles, the locks broke. They had to pull them out and buy new ones. Then, the wall leaked, and they had to pump water 24/7. In the end, he spent double what he would have spent on hot rolled steel sheet pile. At Centerway Steel, we aim for a win-win. We do not want you to save money today only to lose your reputation tomorrow. If your project involves marine environments, high water pressure, or tough driving conditions, the hot rolled option is actually the cheaper choice in the long run because it works the first time.

Hot rolled piles offer superior strength and water tightness, while cold rolled piles save money on simpler projects. Choose the right material to ensure your project's safety and success.