Are you struggling to find reliable steel materials for complex infrastructure projects? Delays and poor quality can ruin your budget. Here is how to choose the right solution. A professional sheet piling supplier provides structural sections with interlocking systems to retain soil or water. Whether using hot-rolled or cold-formed piles, the right partner ensures efficient load transfer, durability, and compliance with project specifications for levees, ports, and foundations.

Many purchasing managers overlook the details of manufacturing methods. This leads to problems later. Let’s look at the specific types of piles available.

Confusion between manufacturing methods causes structural risks. You need the right fit to avoid leaks or wall failures. Hot-rolled piles have tighter interlocks made at high temperatures, offering low permeability for water projects. Cold-formed piles are cost-effective for less harsh conditions. The choice depends on soil hardness and water tightness requirements.

When I look at the global market, I see that understanding the geometry of the pile is vital. The performance depends heavily on how the pile is made. As a sheet piling supplier since 1996, I want to break down the main types we encounter.

Hot-rolled piling is produced at high temperatures. This process creates a very tight interlock. This is crucial if you are building a cofferdam or a wall in the water. The tight lock stops water from passing through. Cold-formed piles are bent into shape at room temperature. The lock is looser. I do not recommend these for very hard driving conditions or where you need a perfect water seal. However, they are cheaper and work well for simple retaining walls.

There are three main shapes you will see in designs:

1. Z-type: These look like a stretched 'Z'. The interlocks are far from the center. This gives them a high strength-to-weight ratio. They are very common in North America and Europe.

2. Flat Web: These are different. They form circles or arcs. We use them to build gravity cells. They rely on the strength of the lock effectively pulling apart (tension), not bending.

3. Pan Type: These are small, cold-formed shapes. They are only for short, light walls. Here is a quick comparison to help you decide:

| Feature | Hot-Rolled Piles | Cold-Formed Piles |

|---|---|---|

| Interlock Tightness | Very Tight (High Water Resistance) | Looser (Low Water Resistance) |

| Driving Conditions | Good for Hard Soil/Rock | Good for Soft/Medium Soil |

| Cost | Higher | Lower |

| Common Use | Ports, Cofferdams, Deep Excavations | Retaining Walls, Canal Banks |

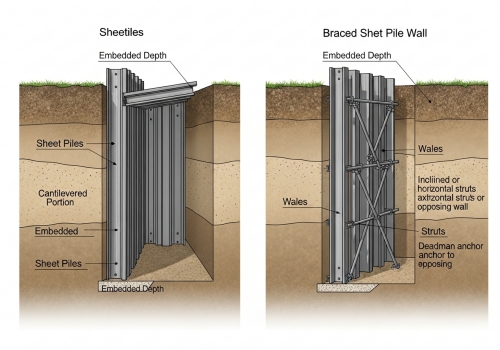

Choosing the wrong method leads to wall failure. This endangers workers and equipment on your site. Braced shoring supports deep excavations with high lateral pressure, while cantilever shoring works for shallower depths. Common applications include levees, cofferdams, and bulkheads. The method depends on excavation depth and soil type.

I have worked with many engineers over the years. They often debate which installation method is best. It usually comes down to the depth of the hole and the type of soil.

Cantilever Shoring: This is the simpler method. The sheet pile is driven deep into the ground. The earth holds the bottom, and the top stands free. It works like a diving board. This is good for shallow excavations. It relies on the pile's own strength to hold back the dirt. Braced Shoring: When you dig deeper, the pressure from the soil gets very high. A simple wall might bend or snap. In this case, we use bracing. We put steel beams or anchors inside the excavation to push against the wall. This gives it extra support. This is vital for deep foundations or when working near heavy traffic.

I supply these products for many different jobs. Here are the most common places you will see them:

· Marine Projects: Breakwaters and bulkheads to stop the ocean.

· Transport: Bridge abutments and underground parking.

· Environmental: Barrier walls to stop pollution from moving in the ground. Below is a guide on where to use each type:

| Application | Recommended Method | Why? |

|---|---|---|

| Shallow Trench | Cantilever | Fast installation, lower cost. |

| Deep Basement | Braced / Anchored | High lateral pressure requires support. |

| Cofferdam | Circular / Braced | Needs to create a dry work environment in water. |

| River Levee | Cantilever | Permanent soil retention along banks. |

Dealing with multiple vendors creates logistical nightmares. Inconsistent quality hurts your reputation and causes project delays. A top-tier sheet piling supplier offers integrated services, including production, testing, and logistics. Look for ISO certifications and a track record with major oil and gas companies. They should offer one-stop sourcing to save costs.

Finding a partner is harder than just buying steel. In my experience at Centerway Steel, customers want more than just a product. They want a solution.

As a purchasing manager, you know the pain of coordinating five different factories. One for pipes, one for fittings, and one for sheet piles. A true integrated sheet piling supplier handles all of this. We integrate production, inventory, and sales. This means you make one phone call, and we handle the rest.

You cannot risk using bad steel. You must check for certifications. Does the supplier have ISO 9001? Have they been inspected by SGS or TUV? These third-party checks are proof of quality. At Centerway, we share our China-made products globally, and we ensure they meet international standards like CE and GOST.

Shipping steel is not easy. It is heavy and large. You need a supplier who understands logistics. We have partners in over 100 countries. We have served giants like CNPC, Shell, and Petronas. This experience means we know how to handle paperwork and shipping terms to get the material to your site on time. Checklist for Choosing a Supplier:

1. Production Capability: Can they handle large diameters or special lengths?

2. Certifications: Do they have ISO and AAA credit ratings?

3. Project History: Have they worked with Fortune 500 EPC companies?

4. Service: Do they offer inspection and after-sales support?

Selecting the right sheet piles and a capable supplier ensures project safety and budget control. Trust a partner with global experience and integrated manufacturing capabilities for success.