Longitudinal submerged arc welded (LSAW) pipes are essential components in modern pipeline infrastructure, requiring precise welding parameters to ensure structural integrity. The multi-wire submerged arc welding (SAW) process has become the industry standard for producing these pipes, offering superior deposition rates and weld quality. This article examines the critical relationship between welding current, arc voltage, and weld bead characteristics in LSAW pipe production.

In longitudinal submerged arc welded pipe production, a typical three-wire system demonstrates distinct current requirements:

1. Leading Wire Current (Primary Penetration Control)

· Typically operates at 900-1200A (depending on pipe wall thickness)

· Accounts for 70-80% of total penetration

· Current variations have 3-4× greater impact on penetration than trailing wires

2. Middle Wire Current (Filler Metal Deposition)

· Generally set at 600-900A

· Primarily affects weld reinforcement height

· Excessive current can cause undercut at weld toes

3. Trailing Wire Current (Finish Control)

· Normally maintained at 400-700A

· Minimal penetration contribution

· Critical for final bead shaping

For optimal results in longitudinal submerged arc welded pipes, maintain these current ratios:

· Leading:Middle:Trailing = 5:3:2 (for thick-wall pipes)

· Leading:Middle:Trailing = 4:3:2 (for standard wall thickness)

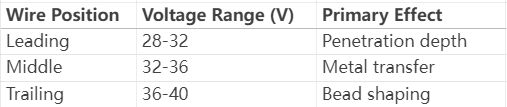

The arc voltage in longitudinal submerged arc welded pipe production directly influences:

· Weld width (0.8-1.2mm width increase per volt)

· Reinforcement shape

· Fusion line smoothness

For systems using AC on trailing wires:

· Maintain 2-4V higher than DC wires

· Frequency should be 20-40Hz for optimal arc stability

· Prevents "gourd-shaped" weld profiles

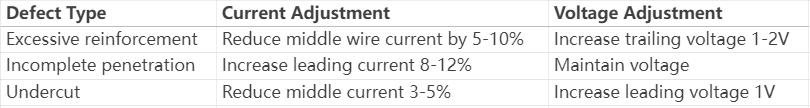

The optimal balance for longitudinal submerged arc welded pipes requires:

1. Stable Power Ratio: Current ratio between wires should remain constant while adjusting overall heat input

2. Progressive Voltage Increase: Ensures proper bead wetting and eliminates undercut

3. Heat Input Control: Should not exceed 50kJ/inch for API-standard pipes

Modern longitudinal submerged arc welded pipe mills employ:

· Real-time parameter tracking with data logging systems

· Automated feedback loops for current/voltage adjustment

· Vision systems for bead profile monitoring

The production of high-quality longitudinal submerged arc welded pipes demands precise control of multi-wire SAW parameters. By implementing the recommended current distributions and progressive voltage profiles outlined above, manufacturers can achieve:

· Consistent penetration in root passes

· Optimal reinforcement profiles

· Defect-free weld surfaces

· Compliance with API 5L and other international standards

Proper parameter optimization not only ensures weld quality but also improves production efficiency in longitudinal submerged arc welded pipe manufacturing, reducing rework and material waste while maintaining high throughput rates.