Sourcing the right steel pipes for major infrastructure projects can be a headache. If you choose the wrong type, you risk project delays, safety hazards, and massive financial losses. LSAW pipe, or Longitudinal Submerged Arc Welded pipe, is the top choice for high-pressure oil and gas transmission. The key lies in understanding the lsaw pipe specification, which includes strict controls on diameter, wall thickness, and material grade (like API 5L) to ensure the pipeline can withstand extreme stress.

Many people think all welded pipes are the same, but that is a dangerous mistake. I will explain the details you need to know so you do not make a bad buying decision.

You might wonder why LSAW pipes are stronger than others. The answer is not just in the steel itself, but in the unique way the factory forms and welds it. The manufacturing process, typically JCOE, directly dictates the final quality. This method ensures the lsaw pipe specification meets high standards for straightness and ovality. It allows for the production of large diameters that seamless pipes simply cannot achieve, making it essential for trunk lines.

I have worked in this industry for a long time, and I see that many buyers do not fully grasp the "JCOE" process. This is the heart of LSAW production. First, we take a steel plate and press it into a "J" shape, then a "C" shape, and finally an "O" shape. This is different from spiral welded pipes which use coils. Because we use steel plates, the quality of the raw material is easier to control. The most important part of this lsaw pipe specification is the "E" – Expansion. After welding, the pipe undergoes mechanical expansion. This step eliminates internal stress in the steel. If you skip this, the pipe might warp under pressure. For an EPC manager, this means the pipe stays round and straight. When your team installs it on-site, the ends fit together perfectly. This saves you welding time and labor costs. We can produce sizes from 16 inches up to 60 inches using this method. This covers almost all major oil and gas needs.

A pipe is only as good as the standard it follows. Without clear rules on chemical and mechanical properties, you are just buying a piece of metal, not a pipeline solution. The most common standard is API 5L. When reviewing an lsaw pipe specification, you must choose between PSL1 and PSL2 levels. PSL2 offers tighter controls on chemicals and fracture toughness, which is critical for sour service or cold environments where safety is the number one priority.

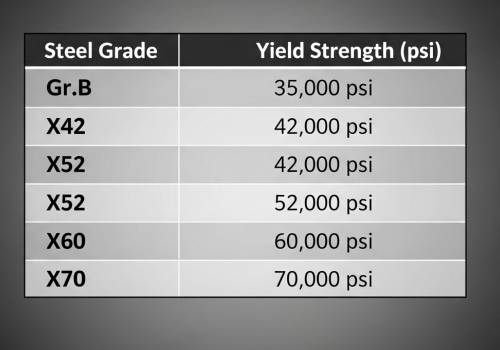

Let us break down the standards because this is where many projects face compliance issues. The global benchmark is API 5L. However, simply saying "I need API 5L pipe" is not enough. You need to specify the Grade and the Product Specification Level (PSL). For general water or low-pressure gas, Grade B might be enough. But for long-distance energy transport, you will likely need X60, X70, or even X80. The "X" stands for the yield strength. X70 means 70,000 psi minimum yield strength. Higher strength allows you to use thinner walls to hold the same pressure, which saves steel weight and transport costs. Also, strict chemical control is vital. We limit elements like Sulfur and Phosphorus to extremely low levels. This prevents the steel from cracking in cold weather or when transporting sour gas. Here is a simple table to help you compare the common grades we supply:

| Grade | Yield Strength (min) | Tensile Strength (min) | Typical Use |

|---|---|---|---|

| Gr. B | 245 MPa | 415 MPa | Water, Structural |

| X42 | 290 MPa | 415 MPa | Low Pressure Gas |

| X52 | 360 MPa | 460 MPa | Oil & Gas Lines |

| X60 | 415 MPa | 520 MPa | Oil & Gas Lines |

| X70 | 485 MPa | 570 MPa | High Pressure/Long Distance |

Finding a supplier is easy, but finding a partner who understands your deadline and quality pressure is hard. You need more than just a price list; you need reliability. Centerway Steel is not just a trader; we are a pipeline integration specialist. We solve the problem of fragmented sourcing by providing a one-stop service for LSAW pipes that meet every rigorous international standard, backed by decades of experience serving Fortune 500 companies.

I know the pressure you face as a purchasing manager. You have a budget to keep and a schedule that cannot slip. At Centerway Steel, we have been doing this since 1996. We do not just sell you a pipe; we check every detail of the specification before production starts. Our products have passed inspections by SGS, BV, and TUV. This means you do not have to worry about the material failing a third-party audit. We handle everything from the steel plate to the final coating and valve integration. This is our "One-stop" promise. We have supplied giants like CNPC, Shell, and Chevron. Whether you need pipes for an offshore platform or a desert pipeline, we have the experience. We can produce heavy wall thicknesses and large diameters that other small mills cannot handle. We treat your project as our own, ensuring the pipes arrive on site, on time, and with the correct paperwork.

Understanding LSAW specs ensures project safety. Always check the manufacturing process, material grade, and supplier reliability. Centerway Steel offers the expertise and quality you need for success.